Thread Gauge Size Chart,How Many Do You Know

Introduction:

The thread gauge size chart is a crucial reference document for determining screw thread size and accurately measuring threads.

It does not matter whether the work is with bolts, nuts, or fasteners (particularly fasteners); dimensions like pitch, diameter, or type of thread are important parts to know when it comes to finding the right fit and compatibility.

The choice is greatly streamlined in this chart, as common thread sizes are indicated in both metric and imperial units. This chart encourages any machinist, engineer, mechanic, or do-it-yourselfer.

This chart, when combined with a thread gauge, can be used to avoid incompatible threads and facilitate accuracy when performing jobs related to manufacturing and repair.

1. What is the thread gauge size chart?

A thread gauge size chart is a broad-based reference book in which standard screw thread sizes, both metric and imperial, major diameter, pitch, and type of thread are presented in tabular form.

It is used to serve the purpose of identifying and comparing Threads accurately so as to fit screws, bolts, and nuts.

| Nominal Size & Threads Per Inch |

Basic Pitch Diameter (Inches) |

Section at Minor Diameter (In²) |

Tensile Stress Area (In²) |

| 3/8-24 | 0.3479 | 0.0809 | 0.0878 |

| 716-20 | 0.4050 | 0.1090 | 0.1187 |

| 12-20 | 0.4675 | 0.1486 | 0.1599 |

| 916-18 | 0.5264 | 0.189 | 0.203 |

| 5/8-18 | 0.5889 | 0.240 | 0.256 |

| 34-16 | 0.7094 | 0.351 | 0.373 |

| 78-14 | 0.8286 | 0.480 | 0.509 |

| 1-12 | 0.9459 | 0.625 | 0.663 |

| 1%8-12 | 1.0709 | 0.812 | 0.856 |

| 11%4-12 | 1.1959 | 1.024 | 1.073 |

| 13/8-12 | 1.3209 | 1.260 | 1.315 |

| 11%₂-12 | 1.4459 | 1.521 | 1.581 |

This chart is often used alongside a thread gauge diagram, which provides a visual tool to view any of the different thread shapes and pitches in a diagram format, and these two charts aid the task of choosing or checking the fit of a thread.

When designing or repairing machinery or doing any DIY work, the thread gauge diagram is indispensable when any tight and accurate joints must be made.

2. What is the application of the thread gauge?

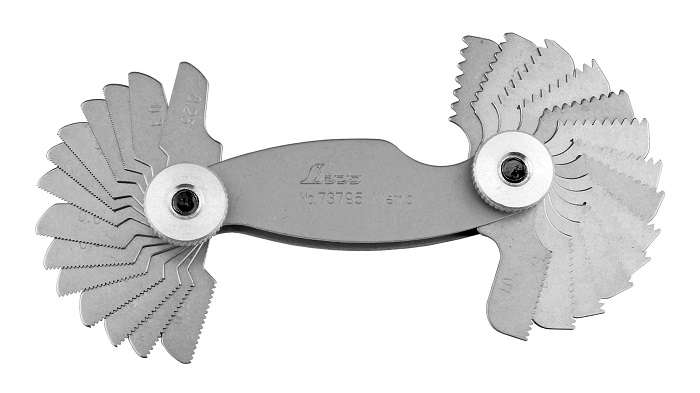

A screw thread pitch and diameter gauge, or simply a thread gauge, is an accurate measuring instrument that determines the pitch and diameter of screw threads.

It mainly measures and checks the size of threads with nuts and bolts, screws, and all pieces of piping.

A thread gauge ensures proper matching of fasteners and mating parts through the presentation of proper measurements to alleviate the problems of cross-threading, loose connections, and errors in assembly.

Thread gauges are needed everywhere - in the field of various industries and applications, where precision and compatibility are decisive:

· Manufacturing and Production

Thread gauges are very important in quality control in the manufacturing sector. They are applied in the thread inspection of machined parts to ascertain that they meet agreed standards.

This aids in consistency, minimizes waste, and reliability of the products in a mass production system.

· Mechanical and Repair Automotive

The thread gauges are common in the workshops and service centers where repairs are carried out on the fasteners or replacements are made by checking the thread size.

This prevents mechanics from applying the wrong screws or bolts that may cause equipment to break or cause injuries.

· Aerospace And Engineering Applications

Thread gauges are unavoidable in high-precision areas such as aerospace and mechanical engineering. They make sure that all the threaded parts possess high tolerances so as to help improve performance and safety in critical systems.

· Pipe Fitting and Plumbing

There are thread gauges that determine which type of thread is on the pipes and fittings, which will give a leak-free and pressure-safe connection with the plumbing fitting system.

· DIY and Home Workshop Use

The thread gauges also facilitate the task of finding out fasteners that can be used by hobbyists and DIY individuals when carrying out work in their homesteads or when repairing their furniture or appliances.

In general, thread gauges are useful in maintaining accuracy, safety, and efficiency in all places where threaded parts are employed.

3. What are thread gauge standards?

Thread gauge standards are the worldwide systems of standards that establish the dimensions, tolerances, and classification of screw threads.

These standards promote uniformity and compatibility of threaded products (i.e., bolts, nuts, and pipes) between the industries and regions.

Purpose of Thread Gauge Standards

The primary point of these standards is to offer uniform direction on making, auditing, and pinpointing thread sizes and kinds. They make it hard to create a mismatched thread, make it safer, and keep production and assembly at a high quality.

Common Thread Gauge Standards

ISO Metric (International Organization for Standardization)

- Applied in metric systems worldwide as a thread system

- Threads that have a dimension and length, such as M10 x 1.5, can be identified in this way.

Unified Thread Standard (UTS)

- Found frequently in the United States, Canada, and certain other nations

- These contain UNC (Unified Coarse), UNF (Unified Fine), and UNEF (Extra Fine) threads

British Standard Whitworth (BSW)

- Elderly UK standard thread size of rough threads

- Confined to antique machinery and other fields of engineering

British Standard Pipe (BSP)

- Plumbing and hydraulic fluid plumbing Pipe thread standard

- Contains BSPT (tapered) and BSPP (parallel) threads

National Pipe Thread (NPT)

- The flattened threading standard used in industrial plumbing and piping in the United States

Why Thread Standards Matter?

The consistent application of a thread gauge lowers the possibility of many parts manufactured by other companies being incompatible.

It also makes identification of the thread easier when a thread gauge or a thread gauge chart is used during inspection or assembly.

4. How to choose the right thread gauge size?

The selection of the correct gauge size of the threads is very crucial in the correct identification and consequent matching of any threaded items, such as screws, bolts, nuts, and pipes.

These are the steps that you can keep in mind to choose the right thread gauge:

· Determine the Thread Type

Determine, first, whether it is an internal (on a nut or hole) or external (on a bolt or screw) thread. In addition to that, find out whether it is metric or imperial. This assists in narrowing the choice of a set of gauges to use.

· Measure Key Diameter

Measure the outside diameter of the threaded portion (on a caliper, a ruler; on internal threads, the inside diameter); then apply the same procedure to the thread that is to be cut in or recessed. This provides you with an entry point to the selection of gauge sizes.

· Use a Thread Pitch Gauge

A thread gauge, where the leaves are identified by pitch sizes, should be selected. Trident thread pitch gauge.

You can match the thread pitch gauge to the threads of your component by inserting the leaves between the threads until you get a perfect match.

· Compare with a Thread Gauge Chart

After you measure the diameter of the thread and match the pitch, use a thread gauge chart to come up with the complete specification (e.g., M8 x 1.25 or 1/4"-20 UNC). This verifies the right size and type of a thread.

· Check the Thread Form and Fit

In the event of the need to check it, refer to the diagram of the thread gauge to compare the shape of the thread (V-shaped, square, or trapezoid) and make sure that the shape of the thread and the angle of it comply with the standard ones.

· Verify with a Good Fastener (Optional)

You can experiment by attempting to fit a known nut of a standard size or bolts to see whether it fits bang on or whether it fits perfectly into the groove.

Selecting an appropriate thread gauge size makes it compatible, foolproof, and creates efficiency in any kind of mechanical or industrial application.

Conclusion

A thread gauge size chart is an essential feature that helps to distinguish and identify suitable screws, bolts, nuts, and pipe fittings with the essential parameters effortlessly.

Using this chart, users may care about the threads' compatibility, minimize errors in assemblies, and succeed in having safety and efficiency achieved at high levels in numerous ways.

Whether you are in manufacturing, mechanical repair, plumbing, or DIY projects, you will find it important to know and use a thread gauge size chart, as well as a diagram, to ensure a precise and rock-solid result on each occasion.

Don't forget to share this post!

Related Products

CONTACT US

Tell us your raw material and working details to get quotations within 24 hours.

WhatsApp Us: +86 159 27 555863

Want the best price & newest metal working machinery buying guide,tips and trends sent straightly to your box?Sign up for Armpro's monthly newsletter,we're free for your consultation and Offer you the most suitable working solutions!

The Buyer's Guide

- Tapping Machine: The Ultimate Buying Guide in 2024

- Electric Tapping Machines:the Ultimate Buying Guide in 2024

- Drilling Machine: The Ultimate Buying Guide in 2024

- Drilling milling Machine:The Ultimate Buying Guide in 2024

- CNC Tapping Machine :The Complete Buying Guide in 2024

- Pipe chafering Machine:The Complete Importing Guide in 2024

- Radial drilling Machine:The Complete Buying Guide in 2024

- Thread rolling Machine:The Complete Buying Guide In 2024

- Pillar Drilling Machine:The Ultimate Buying Guide in 2024