Thread Pitch Chart: A Comprehensive Guide

Introduction

We called it the “thread pitch chart,” which helps clarify the specs of threaded fasteners. It is a reference that engineers, manufacturers, and hobbyists have to decide what kind of thread pitch they require because of the function of the thread in terms of performance and the common usability of mechanical part usage. Perhaps you are creating a new machine or working to repair an existing one and need to understand how a “thread pitch chart” works.

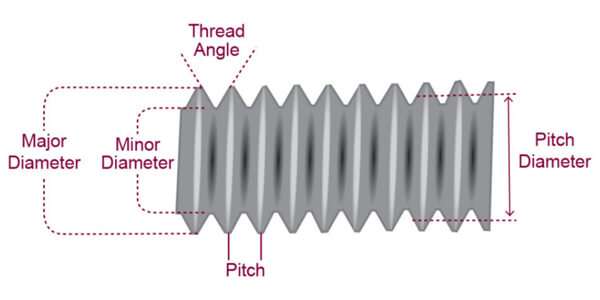

In this article, we shall first introduce the concept of thread pitch and learn the role of the ‘thread pitch chart’. We shall also understand the stern connection between thread pitch and mechanical engineering. Readers need to be familiar with “thread angle”, “thread flank”, “minor diameter”, “pitch diameter”, “major diameter”, and “threads per inch” so that they will be able to determine if the fasteners they purchase are right for their intended application. Let's discuss it in detail now.

1. What is Thread Pitch?

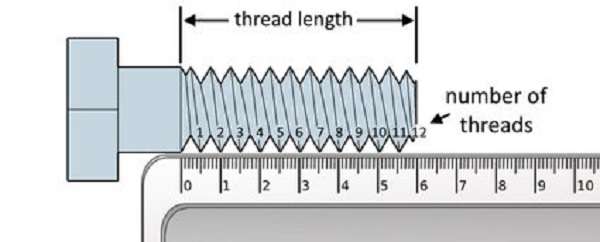

The pitch of a thread describes the spindle distance between two consecutive threads in any given fastener. This measurement helps in determining how a bolt or screw will mate with another surface, like a nut or a threaded hole. This is where the “thread pitch chart” comes in handy, as it brings order – and allows compatibility and function – to these measurements.

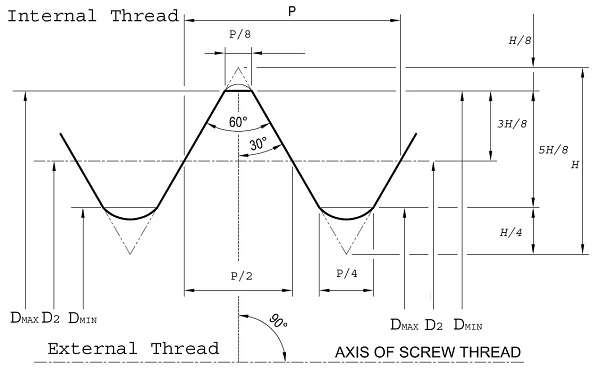

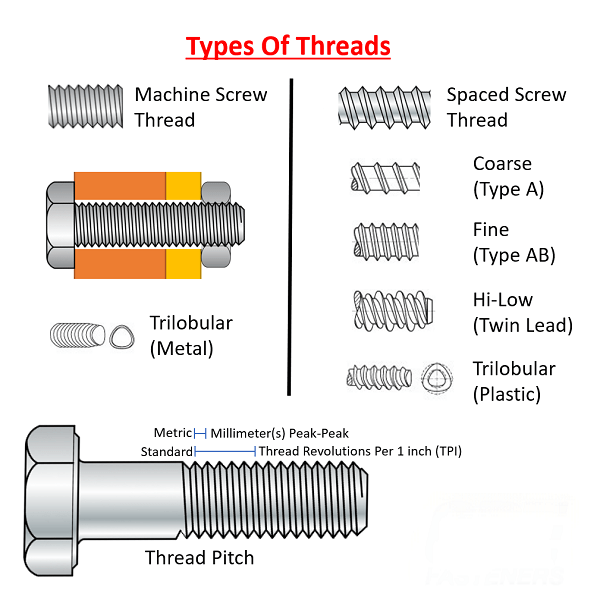

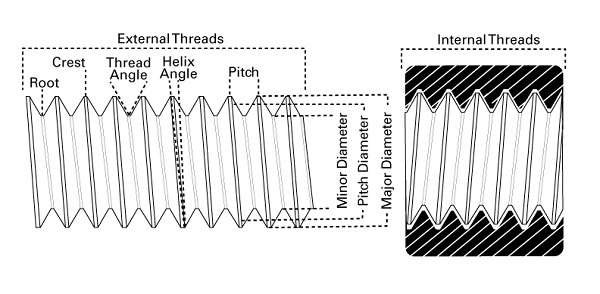

There are several words traditionally associated with thread pitch. First, the thread angle can also be defined as the zero position and is the angle between two adjacent thread flanks. The thread angle differs for every type of thread, though in general use, it has a 60° metric angle and a 55° British angle. This brings Field’s point where he said we have to be aware of the ‘thread angle ’ in order to get the right dimensions, shapes and tolerances on the set parts when they are in use.

The second topography identified is the thread flank, which is the area between the crest and the root of the thread. Consequently, the depth of the thread flank and its geometric form determines the load-bearing capacity within the fastener and the extent of stripping. Thread flank examination in engineering makes it possible to establish the performance of a threaded connection.

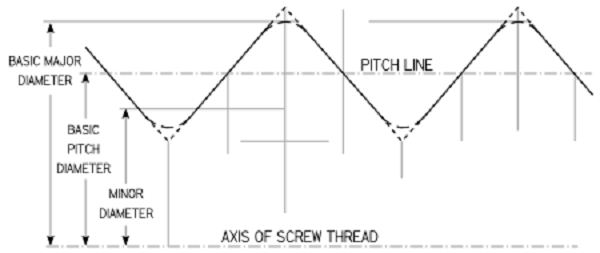

There are others, such as the minor diameter, the pitch diameter and the major diameter. The “minor diameter” is the actual or real minimum diameter of a thread at the root of the thread. The “pitch diameter” is the diameter at which the cross-sectional thickness of the threads is as great as the width of space between threads. The major diameter also exists, which is the maximum outline diameter of a thread, especially on the thread crests. All these are used in profiling the thread, and most of them, together with the pitch, appear as the ‘thread pitch chart’.

The tool is also specified by associating TPI with another parameter: thread pitch. TPM is the number of threads per inch and is mostly used by imperial systems. In this case, the “TP/s value determines the shininess or roughness of the thread, which in turn contributes to the characterisation under various issues.” The knowledge of “threads per inch” is quite useful when using the” thread pitch chart”, as it may help users select the right fastener.

2. What is the Thread Pitch Chart?

A “thread pitch chart’ ‘, is a chart that indicates the various thread specifications in terms of pitch, TPI and thread diameters. This is being utilised not only to identify the thread but also to compare the class of thread so that there will be the correct nut and bolt for a specific usage. The “thread pitch chart” is an essential document that is used in mechanical engineering so that threads attuned to one another in an assembly are standardised.

In most cases, the chart provides information about the “minor diameter,” “pitch diameter,” and the “major diameter” associated with the intended thread size. With the help of a “thread pitch chart,” engineers are able to identify the exact dimensions of a thread and control whether they are needed or not.

The other important elements within the “thread pitch chart” are “thread angle “and “ thread flank”. Such parameters confirm the thread profile standard or the ISO, ANSI, or DIN designations. To illustrate this, the “thread angle” is applied to verify whether the thread will screw into another component well, while the “thread flank” is utilised for determining the sturdiness and load-bearing capability of the thread.

TPM, or “threads per inch”, is another important characteristic of the “thread pitch chart”. By offering the TPI value, the chart helps users compare coarse and fine threads. Lower TPI threads are performed as coarse threads to facilitate quick in and out, whereas higher TPI threads are performed as fine threads, which are stronger and inaccurate fits.

The “thread pitch chart” saves time when choosing the right fastener, as all the relevant information is provided at a glance. No matter whether you are fixing your home furniture or designing a bridge, the "thread pitch chart" will guide you through the process and will help you do the work with perfect precision.

| Nominal Size &

Threads Per lnch |

Basic

Diameter |

Pitch

(Inches) |

Section at Minor Diameter (In²) |

Tensile

Area |

Stress

(In²) |

| 3/8-16 | 0.3344 | 0.0678 | 0.0775 | ||

| 716-14 | 0.3911 | 0.0933 | 0.1063 | ||

| 2-13 | 0.4500 | 0.1257 | 0.1419 | ||

| 16-12 | 0.5084 | 0.162 | 0.182 | ||

| %8-11 | 0.5660 | 0.202 | 0.226 | ||

| 3/4-10 | 0.6850 | 0.302 | 0.334 | ||

| 78-9 | 0.8028 | 0.419 | 0.462 | ||

| 1-8 | 0.9188 | 0.551 | 0.606 | ||

| 11%8-7 | 1.0322 | 0.693 | 0.763 | ||

| 1/4-7 | 1.1572 | 0.890 | 0.969 | ||

| 13/-6 | 1.2667 | 1.054 | 1.155 | ||

| 11%2-6 | 1.3917 | 1.294 | 1.405 | ||

| 13/-5 | 1.6201 | 1.74 | 1.90 | ||

| 2-4% | 1.8557 | 2.30 | 2.50 | ||

| 21/4-4% | 2.1057 | 3.02 | 3.25 | ||

| 2%2-4 | 2.3376 | 3.72 | 4.00 | ||

| 2³/4-4 | 2.5876 | 4.62 | 4.93 | ||

| 3-4 | 2.8376 | 5.62 | 5.97 | ||

| 3%4-4 | 3.0876 | 6.72 | 7.10 | ||

| 312-4 | 3.3376 | 7.92 | 8.33 | ||

| 3³/4-4 | 3.5876 | 9.21 | 9.66 | ||

| 4-4 | 3.8376 | 10.61 | 11.08 | ||

3. Why is Thread Pitch So Important?

Revolutionary thread pitch is one of the most important parameters. They can define the characteristics and durability of the threaded fasteners. This defines the match between a bolt or screw and its counterpart and how it will bear mechanical loads and stress. A thread pitch chart is crucial in standardising and optimising the thread pitch from the use of standard threads to other forms of threads.

The first of these is that thread pitch has the ability to influence the manner and distribution of the load along the course of the given thread. Choosing the adequate thread pitch according to the “thread pitch chart” guarantees that the load will be divided by all available threads. This minimises the probability of thread stripping and improves the fastener's constant.

The size of the threads and their pitch also affect the ease with which the objects have to be assembled and disassembled. Naturally, coarse threads with a large pitch are slightly easier to assemble and cannot be caught when threading. On the other hand, fine threads with lesser pitch give a better-holding force and a considerably less tendency to vibrate. Through the help of the “thread pitch chart”, users can easily determine what pitch is suitable for their use.

Notably, there is also the significance of TPI, or “threads per inch.” The latter is vested in the ability to indicate the threads per inch, which defines the space between the threads and, in turn, determines how well the fastener is suited for a particular environment. For instance, an application that is preferred to have higher tensile strength and close tolerance is good with a large number of threads per inch, while an application that needs to be assembled hastily requires a lesser number of threads per inch.

The other important decision is between the “multi-start threads” and the “single start thread.” “Multi-start threads” are threads with multiple thread starts; it means assembly and disassembly are faster. This makes them good for use in situations that require speedy performance. On the other hand, a “single start thread” has only a single thread start, which makes it safer and more efficient. That is why the “thread pitch chart” contains information about both types of threads, so you will be able to choose the most suitable one for your task. It helps you choose a suitable one from a single-start thread or a multi-start thread.

Therefore, thread pitch is an essential component of threaded fasteners, and the “thread pitch chart” is a remarkable instrument for determining the pitch. Thus, when used in this context, thread pitches can be fine-tuned to deliver improved performance, durability, and reliability to a fastener across any industry.

Conclusion

The “thread pitch chart” is a particular tool that any specialist dealing with threaded fasteners needs. It thus includes the pitch and TPI, respectively, in addition to the fastener diameters, enabling easier selection of threads depending on their necessity in specific applications. Users should also be familiar with “thread angle”, “thread flank”, “minor diameter”, “pitch diameter”, “major diameter”, and “threads per inch” so that they will be able to determine if the fasteners they purchase are right for their intended application.

Let me summarise that thread pitch is a hyperparameter that has a direct impact on performance and functionality attributes such as bearing capabilities and assembly ease. The small chart demonstrated here is called the “thread pitch chart”, and by using it, the engineers and manufacturers are able, therefore, to make better decisions that would enhance the durability of their threads. For instance, when dealing with “multi-start threads” or “single-start threads”, what remains constant is the use of a “thread pitch chart”, which ensures the correct measurement when doing any project.

With the ‘thread pitch chart’ being adopted, you are assured of choosing the correct fasteners for application since the requirements for this market have high tolerances and precision. As easy as changing a doorknob, as difficult as constructing a bridge, the “thread pitch chart” will always help you out.

Don't forget to share this post!

Related Products

CONTACT US

Tell us your raw material and working details to get quotations within 24 hours.

WhatsApp Us: +86 159 27 555863

Want the best price & newest metal working machinery buying guide,tips and trends sent straightly to your box?Sign up for Armpro's monthly newsletter,we're free for your consultation and Offer you the most suitable working solutions!

The Buyer's Guide

- Tapping Machine: The Ultimate Buying Guide in 2024

- Electric Tapping Machines:the Ultimate Buying Guide in 2024

- Drilling Machine: The Ultimate Buying Guide in 2024

- Drilling milling Machine:The Ultimate Buying Guide in 2024

- CNC Tapping Machine :The Complete Buying Guide in 2024

- Pipe chafering Machine:The Complete Importing Guide in 2024

- Radial drilling Machine:The Complete Buying Guide in 2024

- Thread rolling Machine:The Complete Buying Guide In 2024

- Pillar Drilling Machine:The Ultimate Buying Guide in 2024