What is the hydraulic chuck & pneumatic chuck difference ?

What is the different between hydraulic chuck and pneumatic chuck ?

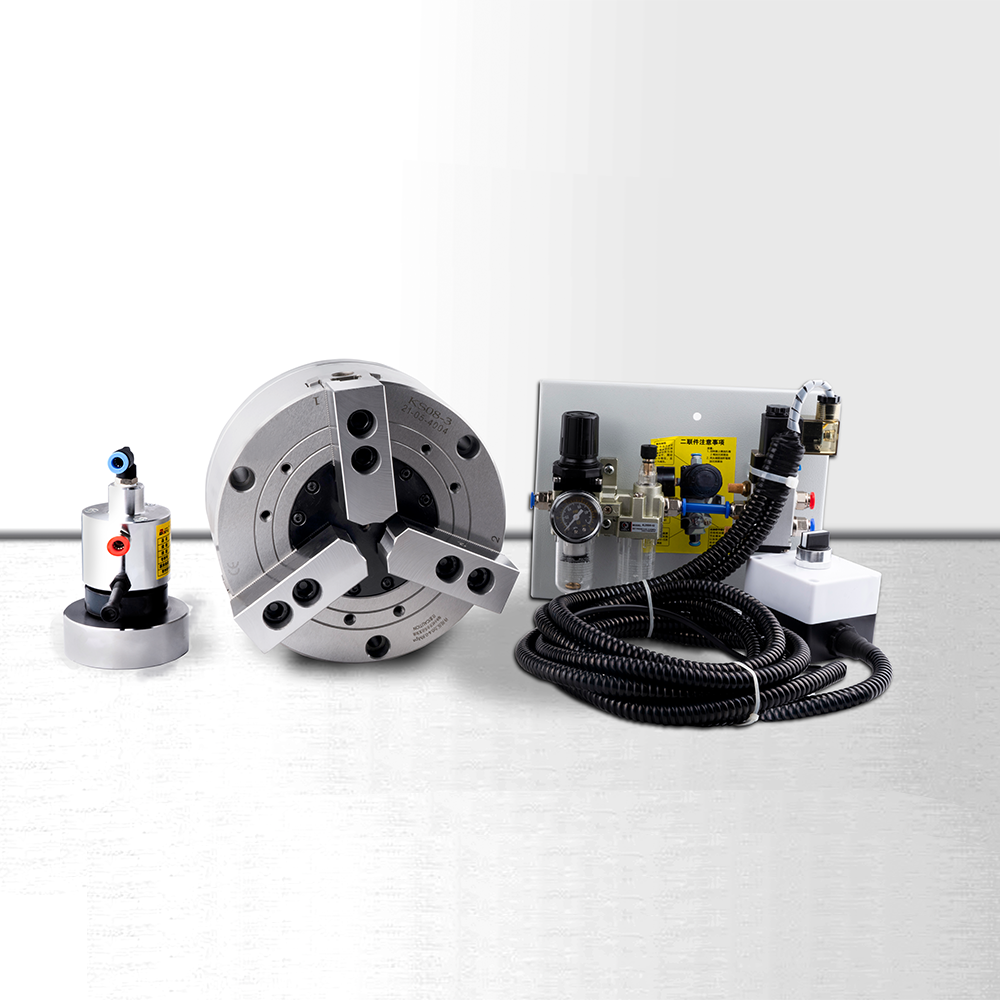

Pneumatic chuck: Air pressure drives the chuck to rotate. The whole set of pneumatic chuck is configured as a chuck, a pneumatic rotator and an electric control part. There is no need for a tie rod during installation. The user only needs to prepare a flange connection plate and a compressed air source to quickly complete the installation of the collet chuck system. And start processing immediately. The pneumatic chuck is mainly composed of trachea and other components! Cylinder built into chuck

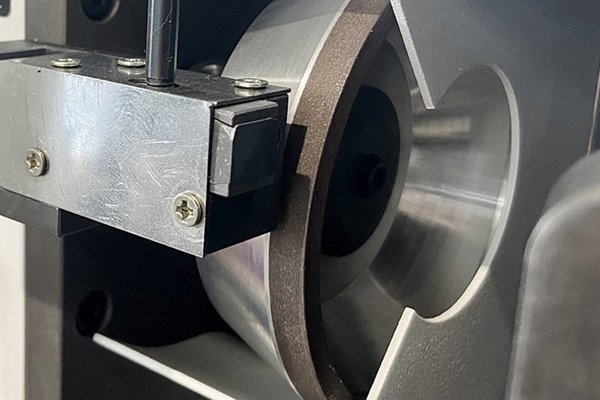

The hydraulic chuck uses a large hydraulic oil stroke (hydraulic oil flow, driven by a hydraulic pump) in exchange for the thrust of the hydraulic cylinder, more hydraulic stability and greater working pressure. Hydraulic stations and hydraulic cylinders are required. Hydraulic chucks are most widely used in CNC lathes. They need to be used in conjunction with high-speed rotary cylinders. The clamping is released by pushing and pulling the cylinders forward and backward. The speed is high and the holding force is stable. It is widely used in automatic lathes all over the world. the widest,

Advantages of pneumatic chuck: high clamping accuracy, long service life; no pollution, convenient and sensitive low-pressure adjustment, and low energy consumption. Disadvantages: Pneumatic instability and easy damage. When installing the pneumatic chuck, there is no need for a tie rod. It is fast. By reading the installation instructions and schematic diagrams, the user can complete the entire installation process in about 1 hour, which not only saves the high installation fee and production cost for the majority of users, but also improves the operation of the machine tool for the user. effectiveness.

The advantages of the hydraulic chuck: the chuck has a large clamping force, stable heavy cutting, and the clamping force can reach 3.5MPa. Disadvantages: dirty, noisy, high energy consumption, low pressure is difficult to adjust.

1) Hydraulic chucks are suitable for heavy loads, and pneumatic chucks are suitable for light loads;

2) The hydraulic chuck system needs to be connected to the oil pipe, and the pneumatic chuck directly discharges the air into the atmosphere;

3) According to the compressibility of the medium, the hydraulic chuck and the pneumatic chuck can specifically solve the special problems in their respective fields;

4) The noise of the pneumatic chuck is larger than that of the hydraulic chuck, and another air source needs to be prepared, and the hydraulic chuck system is equipped with a hydraulic station;

5) The hydraulic chuck has high requirements for oil and is very delicate; the medium of the pneumatic chuck is air, which is much better than the hydraulic chuck oil;

6) The hydraulic chuck uses liquid as the working medium and uses the pressure energy of the liquid to transmit power, while the pneumatic chuck uses compressed air as the power source to drive the machine to complete the telescopic or rotating action.

Compared with the hydraulic chuck, the pneumatic chuck has a simple structure, low cost and failure rate, and is environmentally friendly and pollution-free. It mainly uses air as the power source. Only one 1-cubic air pump can operate 8-10 pneumatic chucks at the same time. In addition, there is no air leakage phenomenon when the pneumatic gyrator is partially clamped and loosened, which can save the air source and reduce the use cost and maintenance cost (such as hydraulic oil) of the hydraulic chuck.

1. Pneumatic is affected by air pressure, the clamping force of the chuck is small, and the clamping force for heavy cutting is unstable, generally below 0.7MPa, and the volume is relatively large. The advantages are no pollution, convenient and sensitive low-pressure adjustment, and low energy consumption.

2. Hydraulic pressure, large clamping force of the chuck, stable re-cutting, the clamping force can be up to 3.5MPa, but the disadvantages are dirty, high noise, high energy consumption, and it is difficult to adjust the low pressure.

1. The medium used in pneumatic transmission is air, and the medium used in hydraulic transmission is hydraulic oil.

2. The hydraulic pressure is higher than the pneumatic pressure, and the power is large. The hydraulic pressure must be used for heavy loads.

3. Hydraulic has higher precision than pneumatic. The cylinder generally has two actions of extending and retracting. The hydraulic action can be varied. After adding a proportional valve or a servo valve, the acceleration and deceleration of the action can be realized.

4. There is a pause during the action. The oil cylinder must be used if the oil cylinder is required to have a pause in the middle position. The cylinder can also stand still but the position deviation is too large.

5. The volume change rate of the gas is too large during compression, and the volume change rate during hydraulic compression is very small.

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 159 27 555 863

Want the best price & newest metalworking machinery buying guide,tips and trends sent straightly to your box?Sign up for Armpro’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Tapping Machine: The Ultimate Buying Guide in 2021

- Electric Tapping Machines:the Ultimate Buying Guide in 2021

- Drilling Machine: The Ultimate Buying Guide in 2021

- Grinding Machine:The Ultimate Buying Guide in 2021

- Metal Band Saw Machine :The Complete Buying Guide in 2021

- Pneumatic Tapping Machine:The Complete Importing Guide in 2021

- Bench Tapping Machine:The Complete Buying Guide in 2021

- CNC Tapping Machine:The Complete Buying Guide In 2021

- Magnetic Base Drill Machine:The Ultimate Buying Guide in 2021

- Drilling And Tapping Machine:The Complete Buying Guide in 2021

Tell us your material or budget,we'll reply you ASAP within 24 hours.