How to choose right power chuck adaper size for your CNC machinery ?

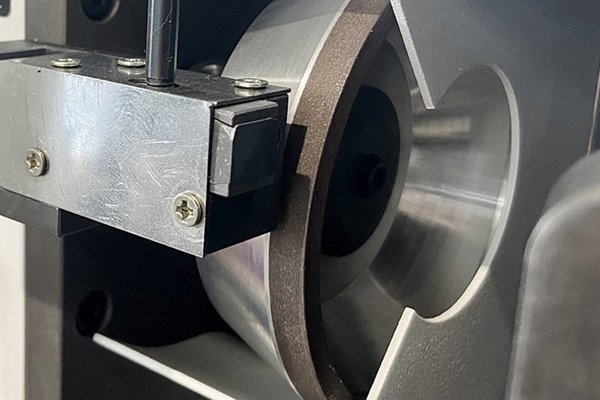

In order to mount your power chuck to your CNC machine spindle, often a precision ground back plate (adaptor) is required to assemble.

Although we can provide many standard types adaptors such as (JIS, ISO or ASA-A1, A2, Camlock or Pull-Stud), we can also supply more widely adaptors or specialist adaptors to suit your special requirements.

Either purchase from our variously standard power chuck stock or provide the essential dimensions you require for your machine spindle to us so that we can supply your high precision adaptor accordingly to meet your requirement.

It’s very neccessary to choose the right direct mount power chuck or hydraulic chuck adapter plate when assembling new or replacing an old power chuck on your machine.

It always some difficult for you to determine what your spindle type is when you don’t know that information in your mind.

we think sometime the easiest way to determine what spindle type is and size is to remove the power chuck and chuck adaptor plate from the spindle nose and measure it carfully, Saving time by using the guide below to quickly and accurately measure your power chuck size .

Common Machine Spindle Types

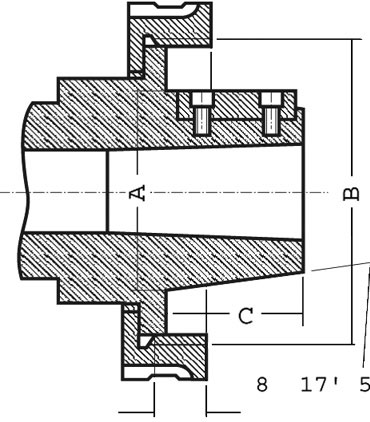

D1 Camlock Spindle DIN 55029, ISO 702/II

Determining D1 Type Spindle and Size

- Measure the pilot diameter and length (B & C)

- Measure the bolt circle diameter (F)

- Measure the diameter of the holes (E)

| Spindle

Nose |

A

(in) |

F

(in) |

B

(in) |

C

max (in) |

E

(in) |

Number

of Holes |

Camlock

Stud Dia (in) |

| D1-3 | 3.622 | 2.7820 | 2.1250 + .00025 | .4375 | .5937 | 3 | 9/16 |

| D1-4 | 4.606 | 3.2500 | 2.5005 + .0005 | .4375 | .6562 | 5/8 | |

| D1-5 | 5.748 | 4.1250 | 3.2505 + .0005 | .5000 | .8750 | 6 | 3/4 |

| D1-6 | 7.126 | 5.2500 | 4.1880 + .0005 | .5625 | 1.000 | 7/8 | |

| D1-8 | 8.858 | 6.7500 | 5.50075 +.0005 | .6250 | 1.125 | 1 | |

| D1-11 | 11.732 | 9.2520 | 7.75075 +.0005 | .6875 | 1.250 | 1 3/16 | |

| D1-15 | 15.866 | 13.0000 | 11.251 + .001 | .7500 | 1.375 | 1 3/8 |

A1/A2 Short Taper DIN 55026, ISO 702/I

Determining an A Type Spindle and Size

- Measure the pilot diameter and length (B & C)

- Measure the bolt circle diameter (F1 and F2) and diameter of the holes (E1 & E2)

- Check the number of bolt circles (one for A2 mount or two for A1 mount)

- All chucks with A1 mount can be installed on A1 spindle nose only

- All chucks with A2 mount can be installed on either a A2 or A1 spindle.

| Spindle

Nose |

F1

(in) |

F2

(in) |

B

(in) |

C

max (in) |

Thread

E1 = E2 UNC-3B |

| A-4 | 3.2500 | - | 2.5005 + .0005 | .4375 | 7/16-14 |

| A-5 | 4.1250 | 2.4374 | 3.2505 +.0005 | .5625 | 7/16-14 |

| A-6 | 5.2500 | 3.2500 | 4.1880 + .0005 | .6250 | 1/2-13 |

| A-8 | 6.7500 | 4.37500 | 5.50075 + .0005 | .6875 | 5/8-11 |

| A-11 | 9.2500 | 6.5000 | 7.75075 + .0005 | .7500 | 3/4-10 |

| A-15 | 13.0000 | 9.7500 | 11.251 + .001 | .8125 | 7/8-9 |

| A-20 | 18.2500 | 14.5000 | 16.251 +.001 | .8750 | 1-8 |

| A-28 | 25.5000 | 20.8750 | 23.001 + .001 | 1.000 | 1 1/4-7 |

L Type Long Taper Key Drive

L Type Long Taper Key Drive

Determining an L Type Spindle and Size

- Measure pilot diameter (A)

- Measure length (C)

- Measure thread size (dimension B)

| Spindle

Nose |

Thread

B |

C

(in) |

A

(in) |

Key |

| L00 | 3 3/4" - 6" | 2 | 2.750 | 3/8 x 3/8 x 1 1/2 |

| L0 | 4 1/2" - 6" | 2 3/8 | 3.250 | 3/8 x 3/8 x 1 3/4 |

| L1 | 6" - 6" | 2 7/8 | 4.125 | 5/8 x 5/8 x 2 3/8 |

| L2 | 7 3/4" - 5" | 3 3/8 | 5.250 | 3/4 x 3/4 x 2 7/8 |

| L3 | 10 3/8" - 4" | 3 7/8 | 6.500 | 1 x 1 x 3 1/4 |

.

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 159 27 555 863

Want the best price & newest metalworking machinery buying guide,tips and trends sent straightly to your box?Sign up for Armpro’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Tapping Machine: The Ultimate Buying Guide in 2021

- Electric Tapping Machines:the Ultimate Buying Guide in 2021

- Drilling Machine: The Ultimate Buying Guide in 2021

- Grinding Machine:The Ultimate Buying Guide in 2021

- Metal Band Saw Machine :The Complete Buying Guide in 2021

- Pneumatic Tapping Machine:The Complete Importing Guide in 2021

- Bench Tapping Machine:The Complete Buying Guide in 2021

- CNC Tapping Machine:The Complete Buying Guide In 2021

- Magnetic Base Drill Machine:The Ultimate Buying Guide in 2021

- Drilling And Tapping Machine:The Complete Buying Guide in 2021

Tell us your material or budget,we'll reply you ASAP within 24 hours.