what is the NPT and NPTF Taper Threads difference

When our Amercia client start tapping work, they always make NPT tapping, NPT stands for National Pipe Taper,

which is widely applied in many different applications, such as: Fuel Systems,Pumps,Regulators,Filters,Aftermarket Brake Calipers,

Oil & Coolant Passages in,Intake Manifolds,Cylinder Heads,Engine Blocks,Gauges,Etc.

also known as ANSI/ASME B1.20.1 pipe threads.

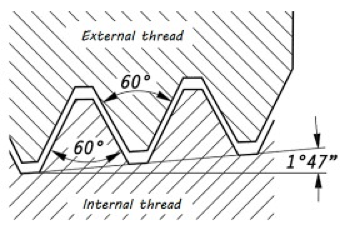

It is a U.S. standard for measuring tapered threads.

Unlike straight threads, a taper thread will provide a closer seal.

Commonly applied sizes include: 1/8, ¼, 3/8, ½, ¾, 1, 1 ¼, 1 ½, and 2 in.

When tapping materials ready, taps and tapping machine received from Armpro Machine. The job is now out in your shop to be done, while first procedure is to drill a hole before tapping.

How do you think what should do ?

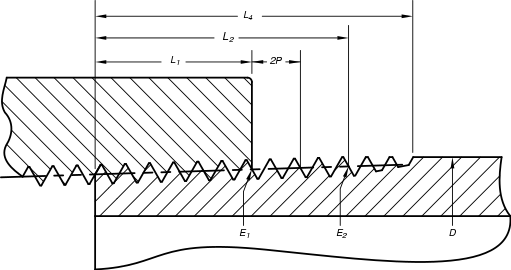

Holes before tapping are produced either straight or tapered, upto your metal working experiences, some will take additional reaming operation on the hole, which can achieve better finish and reduce in tapping torque,

A straight-drilled hole that has not been reamed has much volume of chip removal during tapping. That tap has to not only cut the thread but shape the hole to the correct taper, so more material is removed in the process compared with reamed hole. Every tooth is cutting a new chip like the chamfer of a cylindrical tap. So some client may take interrupted-thread tapper tap for better performance

However tappered or straight hole size needs to be small enough so that the tap produces 100% of the product thread form, else whether hole with or without taper reaming need to be enough deep to meet thread requirement. Also depend on the materials, tapping operation ,style of drill, it is advised that you can run a trial work before run a large quantity of parts

That chart below showing suggested drill size and depth,good size hole to ahiceve good taps performance when do NPT Tapping,

| NPT AND NPTF Tap Drill Size | ||||||

| Size | Minor dia at small end of the ext NPT Taps Ko | Without using a Reamer | With using a Reamer | Tap drill depth (Min) | ||

| Inch | Metric | Inch | Metric | |||

| 1/16–27 | 0.2415 | 0.242 | 6.1 | 0.234 | 5.9 | 39/64 |

| 1/8 – 27 | 0.3338 | 0.332 | 8.4 | 21/64 | 8.25 | 39/64 |

| 1/4 – 18 | 0.4329 | 7/16 | 11 | 27/64 | 10.7 | 55/64 |

| 3/8 – 18 | 0.5675 | 9/16 | 14.5 | 9/16 | 14 | 7/8 |

| 1/2 – 14 | 0.7014 | 45/64 | 18 | 11/16 | 17.5 | 1-7/64 |

| 3/4 – 14 | 0.9106 | 29/32 | 23 | 57/64 | 22.5 | 1-7/64 |

| 1 – 11-1/2 | 1.1441 | 1-9/64 | 29 | 1-1/8 | 28.5 | 1-11/32 |

| 1-1/4–11-1/2 | 1.4876 | 1-31/64 | 38 | 1-15/32 | - | 1-3/8 |

| 1-1/2–11-1/2 | 1.7266 | 1-23/32 | 44 | 1-45/64 | - | 1-25/64 |

| 2–11-1/2 | 2.1995 | 2-3/16 | 56 | 2-11/64 | - | 1-3/8 |

| 2-1/2–8 | 2.6195 | 2-39/64 | - | 2-37/64 | - | 1-61/64 |

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 159 27 555 863

Want the best price & newest metalworking machinery buying guide,tips and trends sent straightly to your box?Sign up for Armpro’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Tapping Machine: The Ultimate Buying Guide in 2021

- Electric Tapping Machines:the Ultimate Buying Guide in 2021

- Drilling Machine: The Ultimate Buying Guide in 2021

- Grinding Machine:The Ultimate Buying Guide in 2021

- Metal Band Saw Machine :The Complete Buying Guide in 2021

- Pneumatic Tapping Machine:The Complete Importing Guide in 2021

- Bench Tapping Machine:The Complete Buying Guide in 2021

- CNC Tapping Machine:The Complete Buying Guide In 2021

- Magnetic Base Drill Machine:The Ultimate Buying Guide in 2021

- Drilling And Tapping Machine:The Complete Buying Guide in 2021

Tell us your material or budget,we'll reply you ASAP within 24 hours.