BSPT–British Standard Pipe Taper Thread size chart

BSPT stands for British Standard Pipe Taper and is a type of threading standard that is commonly used in plumbing and pipe fightings in the UK and various other countries. The BSPT thread system is designed in a way to create a leak-tight seal during the connection of pipes and fittings. Some key features of BSPT:

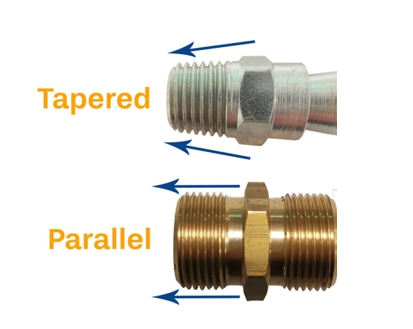

- Tapered threads:BSPT threads are tapered, which means the diameter of the threads gradually decreases along the length of the pipe. This helps to create a tight seal as the threads are tightened together.

- Whitworth Thread Profile:BSPT threads follow the Whitworth thread profile, which is a standardized thread form. This standardisation ensures the compatibility between different BSPT components.

- Requirement of sealant:In order to achieve a reliable seal, it is common to use a thread sealant or tap when assembling BSPT fittings. The use of sealant helps prevent leaks and provides additional security.

- Common use:BSPT threads are widely used in various plumbing applications, especially in the United Kingdom and other regions which follow the constant British standards. Most commonly, they are found to be used in water and gas pipes, as well as in pneumatic and hydraulic systems.

The BSPT threads cannot be replaced with other thread standards like NPT, which are used in the United States. Attempting to mix BSPT and NPT fittings without proper adapters may lead to leaks and compatibility problems. It may also result in leaks and improper fittings. Therefore, when working with BSPT threads, it's essential to use the correct components and accurate measurements and follow the recommended assembly procedures to ensure a leak-free connection.

1. What is BSPT - British Standard Pipe Taper Parameter?

There are some key parameters that define BSPT threads.

They are as follows:

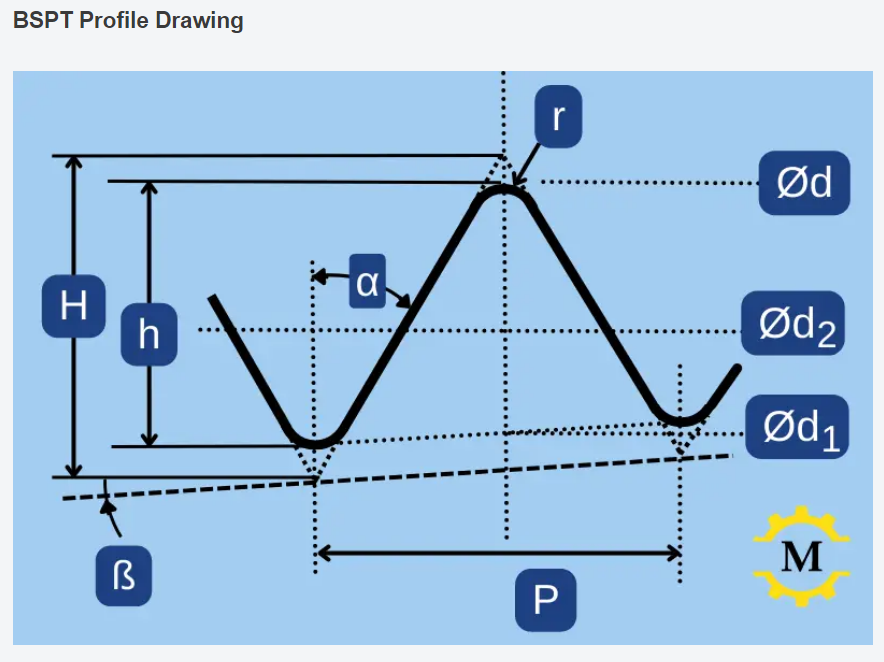

Taper angle: The taper angle for BSPT threads is 55 degrees. It means the threads gradually taper along the length of the pipe fitting from the centerline at an angle of 55 degrees.

Thread Pitch: BSPT threads are made with a specific pitch. It is the distance between the consecutive threads. The thread pitch can differ based on the size of the pipe, but it is standardised for each size.

Thread profile: BSPT threads follow the Whitworth thread profile, which is a specific thread form which has rounded crests and roots. This thread profile gives a tight seal when assembly is done in a proper manner.

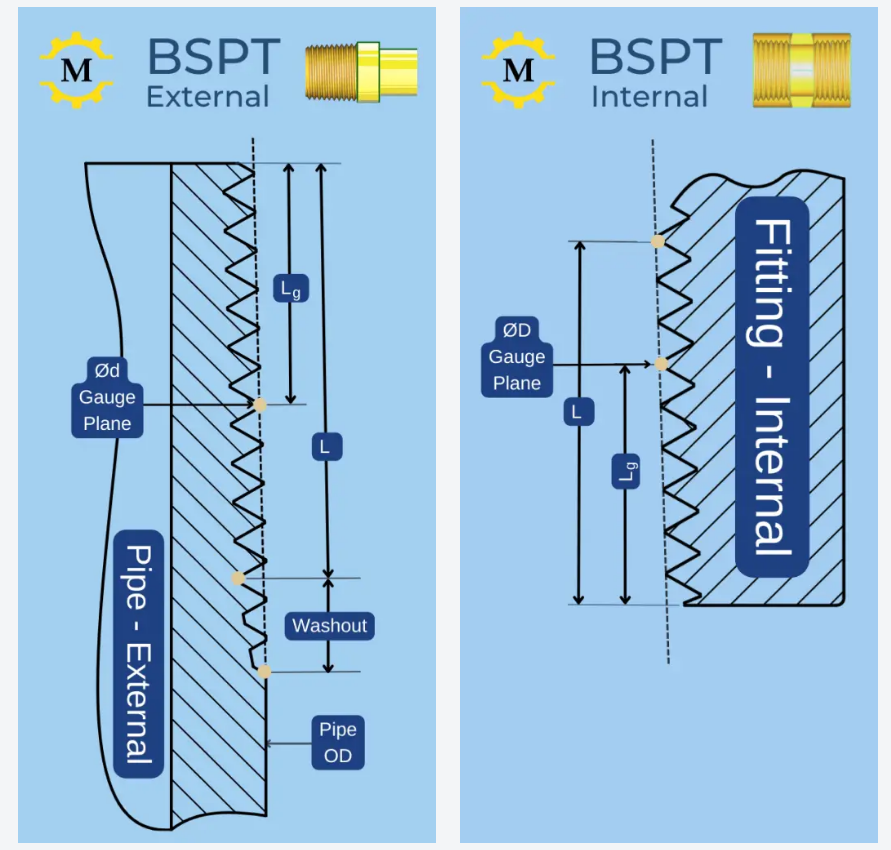

Diameter:BSPT threads are specified by their nominal pipe size (NPS). This corresponds to the inner diameter of the pipe. The outer diameter of the thread varies based on the size and the pitch of the threads.

Thread engagement: The recommended thread engagement, or the depth to which the threads should be engaged, is an important parameter that is required to ensure a proper seal. Each BSPT thread is pecifically provided with its own thread engagement.

Sealant requirement:BSPT threads often require the use of a thread sealant or tape in order to ensure a leak-tight connection. The choice of the sealant or tape and the proper application methods are important factors in achieving a reliable seal.

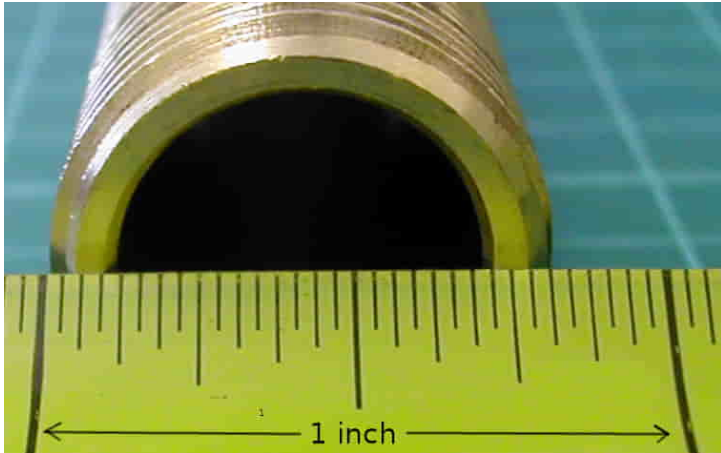

2. What is the BSPT - British Standard Pipe Taper Size Chart?

The BSPT size chart provides information about the various sizes and dimensions of tapered pipe threads thatare used in plumbing and other pipe-fitting applications. Below given is a simplified BSPT size chart for common sizes.

BSPT R (External Tapered) Dimensions Chart

BSPT Rc (Internal Tapered) Dimensions Chart

BSPT Rp (Internal Parallel) Dimensions Chart

3.What is the application of BSPT - British Standard Pipe Taper?

Thread rolling machine, hydraulic thread rolling machine, thread rolling die

BSPT threads are commonly used in a variety of applications, most often in plumbing, fluid transport, and pipe fitting systems. Below given are some key applications of BSPT threads.

Plumbing systems:BSPT threads are widely used in plumbing applications for both residential and commercial buildings. They are used to connect pipes, fittings and fixtures such as faucets, showerheads and valves. The tapered design of the BSPT thread helps to create a leak-tight connection.

Hydraulic systems: BSPT threads are also used in hydraulic systems where the sealing of hydraulic fluid is critical. These threads are used to connect various hydraulic components, including pumps, cylinders and hoses.

Pneumatic systems:Pneumatic systems that use compressed air usually employ BSPT threads to connect components like pneumatic valves, actuators and airlines. The tape angle and thread sealant help prevent air leaks.

Water supply lines:BSPT threads are used in water supply lines to connect pipes and fit in applications such as irrigation systems, water supply for industrial processes, and outdoor water features.

Oil and fuel systems: They are employed in oil and fuel systems, including those in vehicles, to connect various components such as fuel lines, oil filters and oil pressure sensors.

Water supply lines: BSPT threads are used in water supply lines to connect pipes and fittings in applications such as irrigation systems, water supply for industrial processes and outdoor water features.

It is important to consider that although BSPT threads are widely used they are not interchangeable with other threading standards like NPT. Mixing different thread standards can result in leaks and compatibility issues. Therefore, it is crucial to use the correct threading standards for your exact application and ensure proper installation with the appropriate sealant or tape to create leak-tight connections.

4. How to make BSPT–British Standard Pipe Taper?

Creating a BSPT threaded connection involves proper machining and assembly of pipes and fitting with BSPT threads. Materials and tools that are needed in order to achieve this are most commonly, pipes or fitting, thread sealant or tape, and pipe wrencher or spanner.

It is essential to follow the guidelines and standards specific to your application and region when working with BSPT threads. In addition to this, it is important to consider safety precautions, such as turning off the water or fluid supply before making connections, especially in pressurized systems.

5. Conclusion

BSPT is a threading standard which plays a crucial role in applications like plumbing, fluid transporting and pipe fitting.

They are used especially in regions where British standards are adhered to. The tapered design, standardized thread profile and compatibility of BSPT ensure secure and leak-tight connections.

Moreover, it is important to use accurate sizes, thread sealant, and proper installation techniques to guarantee the reliability of BSPT connections. By understanding and implementing BSPT standards, professionals in various industries can make sure of the integrity and safety of their piping systems, meanwhile contributing to efficient and trouble-free operations.

Don't forget to share this post!

Related Products

CONTACT US

Tell us your raw material and working details to get quotations within 24 hours.

WhatsApp Us: +86 159 27 555863

Want the best price & newest metal working machinery buying guide,tips and trends sent straightly to your box?Sign up for Armpro's monthly newsletter,we're free for your consultation and Offer you the most suitable working solutions!

The Buyer's Guide

- Tapping Machine: The Ultimate Buying Guide in 2021

- Electric Tapping Machines:the Ultimate Buying Guide in 2021

- Drilling Machine: The Ultimate Buying Guide in 2021

- Grinding Machine:The Ultimate Buying Guide in 2021

- Metal Band Saw Machine :The Complete Buying Guide in 2021

- Pneumatic Tapping Machine:The Complete Importing Guide in 2021

- Bench Tapping Machine:The Complete Buying Guide in 2021

- CNC Tapping Machine:The Complete Buying Guide In 2021

- Magnetic Base Drill Machine:The Ultimate Buying Guide in 2021

- Drilling And Tapping Machine:The Complete Buying Guide in 2021

Most Popular

Tell us your material or budget,we'll reply you ASAP within 24 hours