How to Tap Effectively and Optimize Tool Life

To minimize hydraulic/electric tapping machine issues the following rules should be followed:

1• Use a pitch controlled tapping attachment in tapping machine.

2• Choose the correct lubricant in tapping machine

3• Use the correct tapping drill size and type of tap in tapping machine.

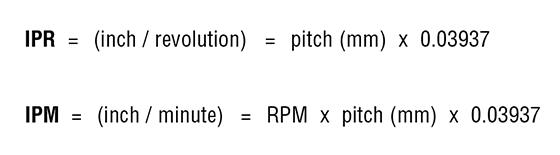

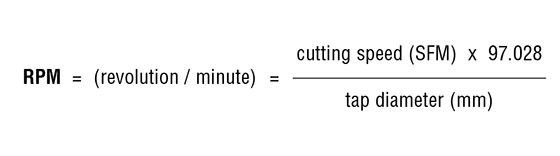

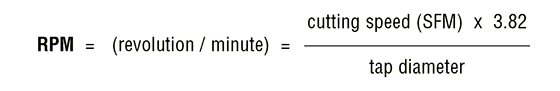

4• Choose the correct Speeds and Feeds in tapping machine.

ARMPRO hydraulic/electric tapping machine actually recommend 68% to 78% percentage of tapping for most metalworking applications because hydraulic/electric tapping machine significantly decrease the torque force required to tap without giving up much drilling & tapping strength.

That means you’re way not possible to break the taps tools in drilling & tapping process, and are sacrificing very less holding strength with hydraulic/electric tapping machine

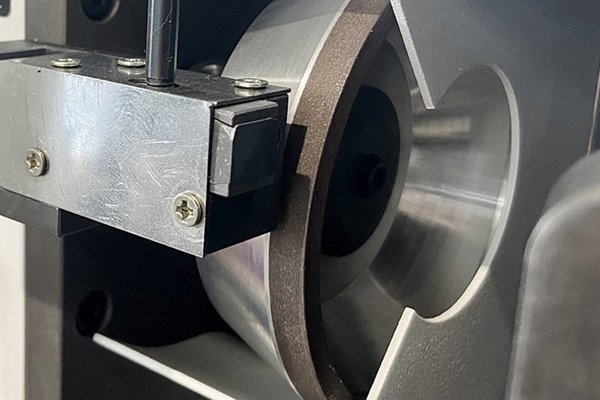

Tapping SpeedsProper tapping machine speeds are very important in obtaining efficient hydraulic/electric tapping machine tapping results. The optimum speed for hydraulic/electric tapping machine tapping is highest speed that conditions permit, consistent with acceptable taps tool life. hydraulic/electric tapping machine Speeds must be reduced with length of hole increases. Holes, taps with tapered chamfers are able to operate faster than taps with botto chamfers. hydraulic/electric tapping machine vertical tapping speeds can be increased, compared to horizontal tapping, because the we can ensure Verticality more easily

Using coolant Oil

When drilling and tapping with ARMPRO hydraulic/electric tapping machine, it is crucial to use coolant oil. It keeps the bits from squealing, makes the cut taps more smoother, cleans out the chips easily, and keeps the drill and stock from overheating to avoid taps break.

Pecking tapping

Pecking tapping helps ensure that taps tools won’t overheat and break taps when using ARMPRO hydraulic/electric tapping machine to tap. Peck tapping involves tapping some times through a part, then retracting it to remove chips, simultaneously allowing the piece to cooling and taps easiyly without obstucle. Our tapping machine with peak tapping model automatically, no need manual operation Whenever the tap is stopped, remove as many chips as possible and then add coolant oil to the surface between the drill tap and the workpiece. , our coolant oil also automatic generated

Using coolant Oil

When drilling and tapping with ARMPRO hydraulic/electric tapping machine, it is crucial to use coolant oil. It keeps the bits from squealing, makes the cut taps more smoother, cleans out the chips easily, and keeps the drill and stock from overheating to avoid taps break. Our ARMPRO hydraulic/electric tapping machine with automatic lubbrication system to make adding coolant oil no need manual

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 159 27 555 863

Want the best price & newest metalworking machinery buying guide,tips and trends sent straightly to your box?Sign up for Armpro’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Tapping Machine: The Ultimate Buying Guide in 2021

- Electric Tapping Machines:the Ultimate Buying Guide in 2021

- Drilling Machine: The Ultimate Buying Guide in 2021

- Grinding Machine:The Ultimate Buying Guide in 2021

- Metal Band Saw Machine :The Complete Buying Guide in 2021

- Pneumatic Tapping Machine:The Complete Importing Guide in 2021

- Bench Tapping Machine:The Complete Buying Guide in 2021

- CNC Tapping Machine:The Complete Buying Guide In 2021

- Magnetic Base Drill Machine:The Ultimate Buying Guide in 2021

- Drilling And Tapping Machine:The Complete Buying Guide in 2021

Tell us your material or budget,we'll reply you ASAP within 24 hours.