Top 10 CNC gear grinder machine manufacturers in the world

Find the top 10 global CNC gear grinder machine manufacturers on the advancement of gear machining. Choosing the right manufacturer is just as important as acquiring the right broaching tool for CNC gear grinders due to their significant impact on contemporary manufacturing processes. Computer numerical control (CNC) gear grinders are essential to the manufacturing of high-quality gear components in many different industries.

Before you go out and get a CNC gear grinder machine , there are a few things you need to take into consideration.

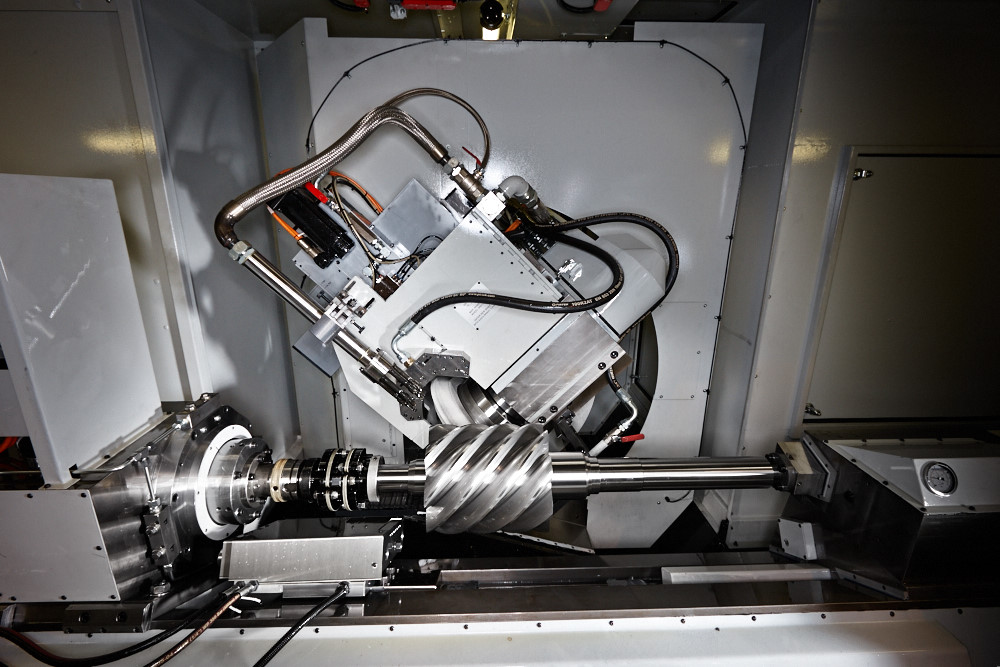

What are CNC gear grinder machine?

CNC stands for "Computer Numerical Control" and uses computer technology to control machine equipment. Within the context of our conversation, these tools stand in for grinding machines that can shape the workpiece in various ways.

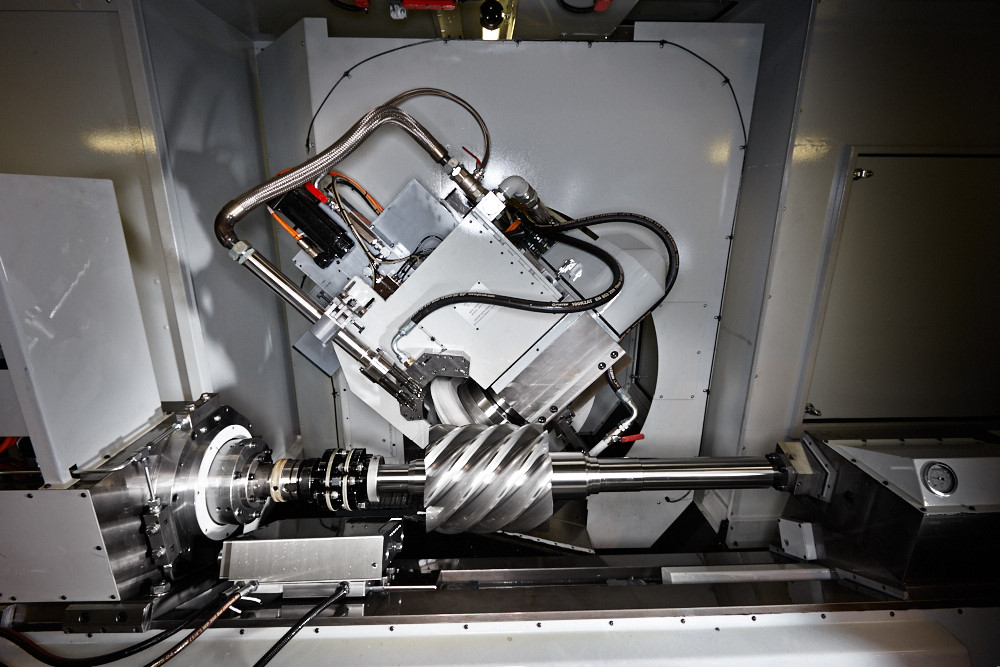

CNC gear grinder machines are modern machining machines used in the precision production of gears. These gear-making machines use computer numerical control (CNC) technology to automate the grinding operation, ensuring that the gears are consistently high quality.

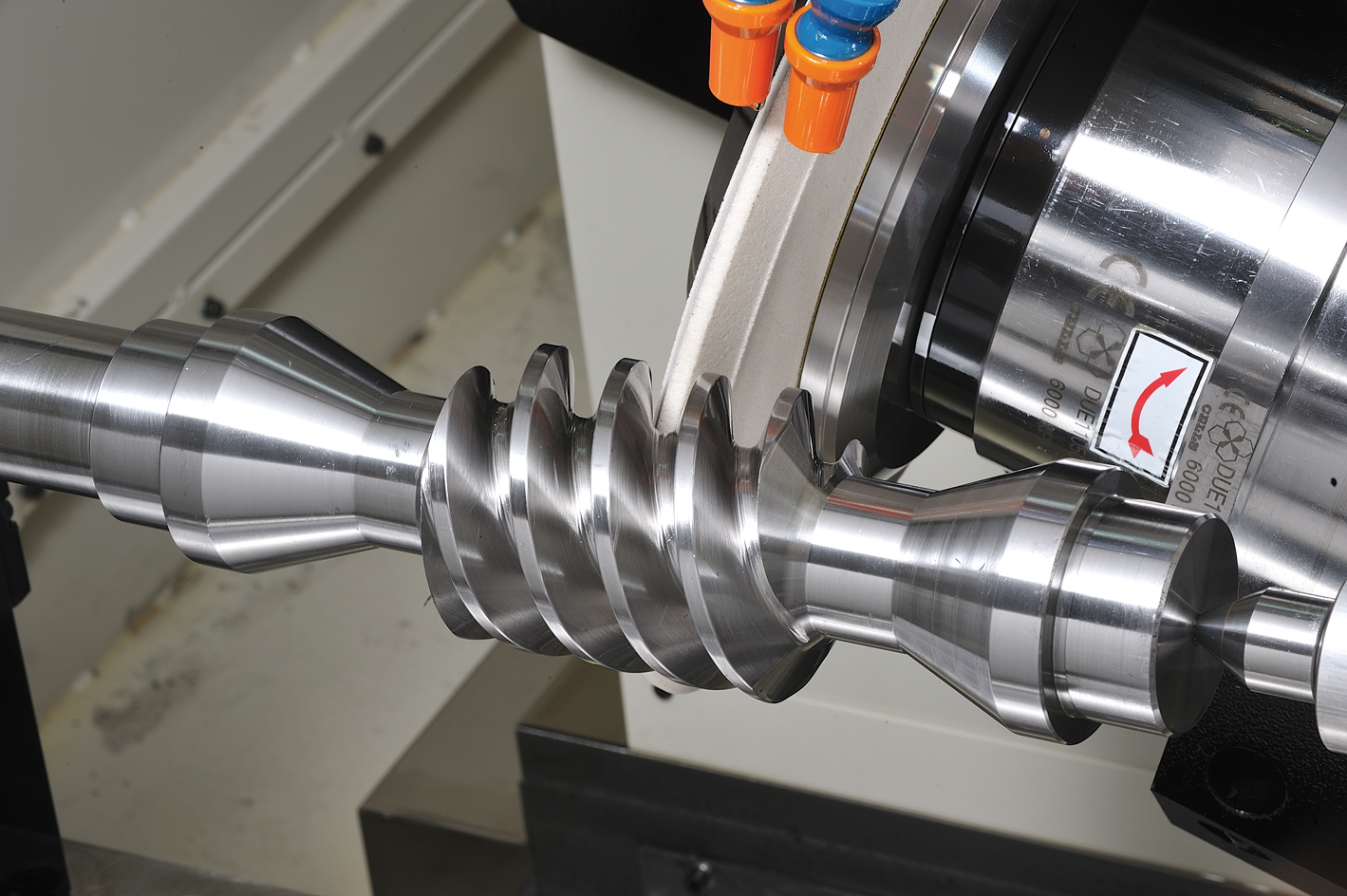

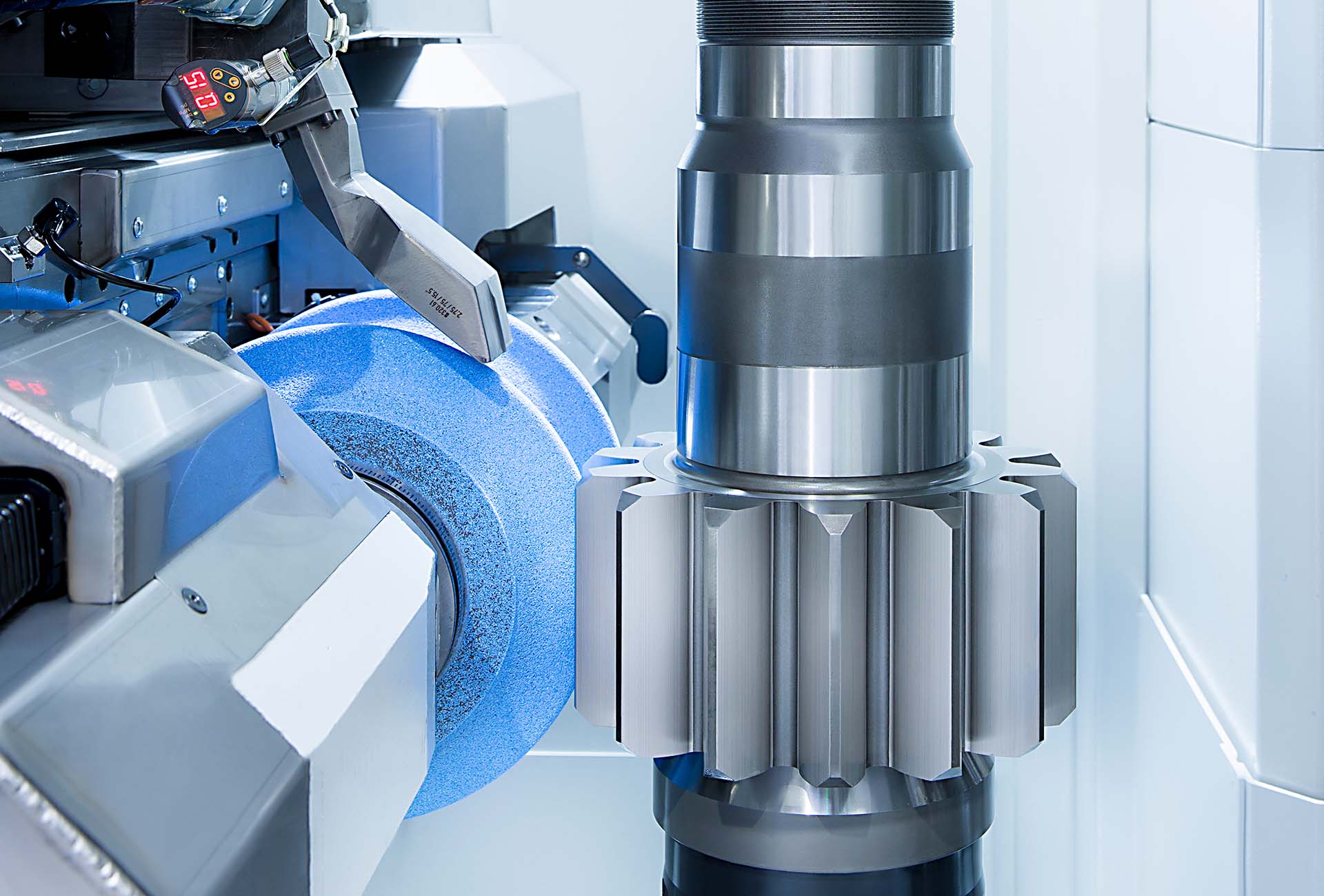

Computer numerically controlled gear grinders increase gear profile and form to strict specifications by rotating abrasive grinding wheels. Many gears are handled. Gears: spur, helix, bevel, worm.

How to Make an Informed Decision When Purchasing Gear Grinder machines?

To make a good purchase of CNC gear grinder machines, you must consider some factors initially.

- Quality and durability:Choose gear grinder machines from reputable companies with a track record of client satisfaction. Strong designs and high-quality parts make machines last longer and require less maintenance.

- Adaptability and Accuracy:Choose machines with a variety of gear sizes and types to grind different materials. So, process flexibility is guaranteed and many gear profiles can be ground. Finding precise, accurate gear grinders is essential for making gears that fulfill high standards.

- Cost:Think About the Total Cost of Ownership (TOT), Incremental Costs, and ROI. Efficiency and long-term worth are more important than short-term gains.

- Compatibility with integration:Make sure the gear grinder machine works well with all of your current automation, software, and production systems. To maximize the effectiveness and efficiency of workflows, compatibility and interoperability are crucial.

Considering these factors will help you choose the CNC gear grinder machines that are ideal for your demands and specifications.Here is the grinder machine brands.

Top 10 CNC gear grinder machine manufacturers brands in the world

| Rank | Manufacturer | Headquarter |

| 1 | REISHAUER | Switzerland |

| 2 | KAPP NILES | Germany |

| 3 | Gleason | USA |

| 4 | KLINGELNBERG | Switzerland |

| 5 | Star SU | USA |

| 6 | Liebherr | Germany |

| 7 | Kanzaki | Japan |

| 8 | Emag AG | Germany |

| 9 | FFG | Germany |

| 10 | Helios | USA |

1.REISHAUER

Here is the first grinder machine brand.

Reishauer is a Swiss manufacturer known for its precision gear grinding solutions. With over 200 employees, the company focuses on innovation and quality.

Key Products:

- Gear Grinding Machines

- Diamond and CBN Dressing Tools

- Gear Honing Tools

- Software Solutions

Reasons for Recommendation:

- Innovation and quality

- Trustworthy and capable of delivering excellent results.

2.KAPP NILES

Profile: Here is the second grinder machine brand.Kapp Niles is a German manufacturer specializing in gear technology and machine tools. With a global presence, the company offers comprehensive solutions for gear grinding and gear cutting.

Key Products:

- Gear Grinding Machines

- Gear Honing Machines

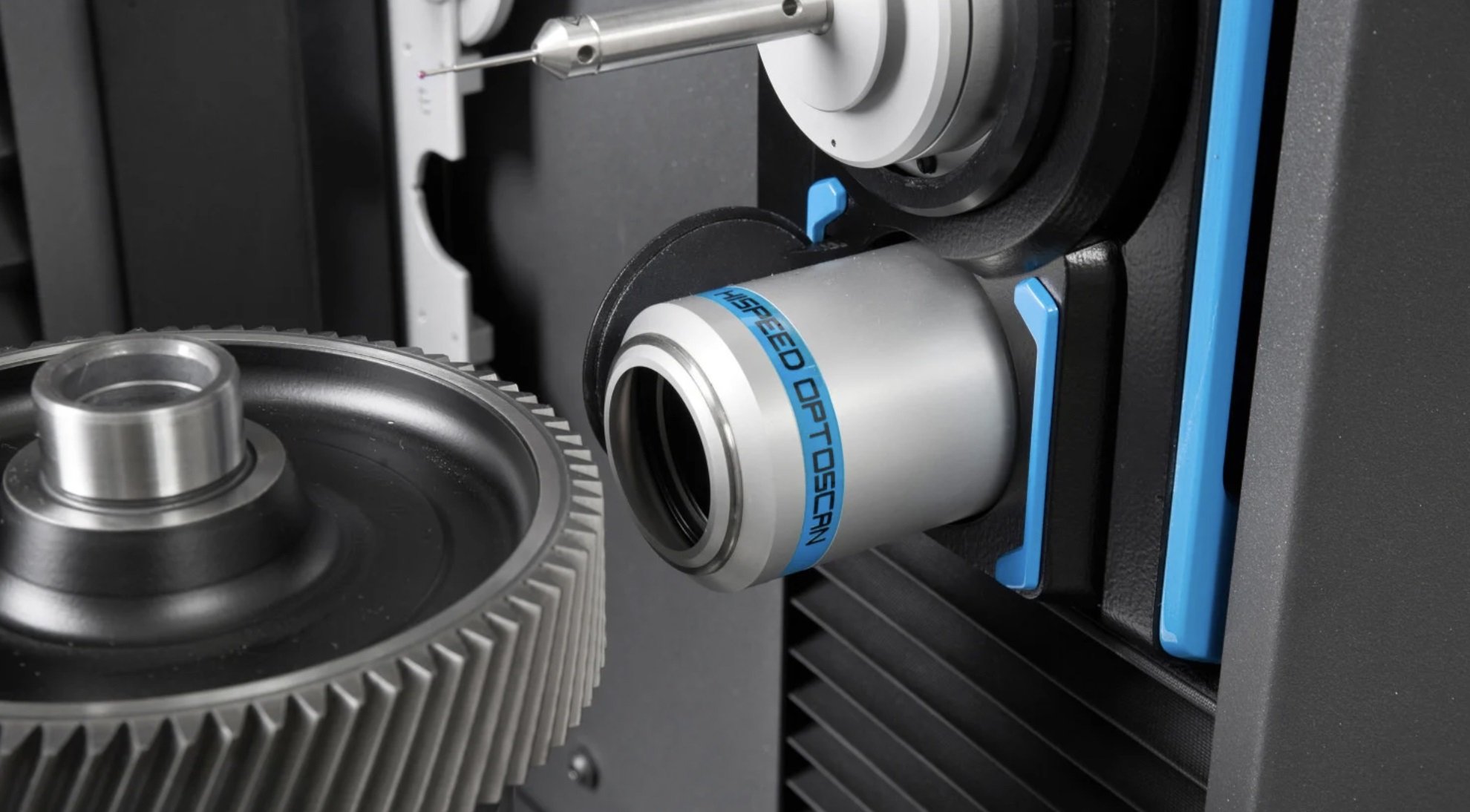

- Gear Measuring Machines

Reasons for Recommendation:

- Deep knowledge of the industry and dedication to pushing technology.

- Trusted partner for companies seeking.

- Cutting-edge gear manufacturing solutions.

3.Gleason

Profile: Here is the third grinder machine brand.

Gleason is an American manufacturer with a long history of innovation in gear technology. The company offers a wide range of gear manufacturing solutions, including gear grinding machines.

Key Products:

- Gear Cutting Machines

- Gear Inspection Equipment

- Bevel Gear Technology

Reasons for Recommendation:

- Well-known invention

- Companies prefer it because of its quality and customer support.

- Cutting-edge methods for gear grindings.

4.KLINGELNBERG

Profile: Klingelnberg is a Swiss manufacturer specializing in gear technology and precision measuring instruments. With a focus on quality and innovation, the company serves various industries worldwide.

Key Products:

- Gear Cutting Machines

- Gear Inspection Equipment

- Bevel Gear Technology

- Software Solutions

Reasons for Recommendation:

- Dedication quality.

- Excellence, accuracy, and happy customers.

- Dependable gear-grinding machinery.

5.Star SU

Profile: Star SU is an American manufacturer specializing in gear-cutting tools, machine tools, and gear-grinding solutions. Focusing on innovation and customer service, the company serves diverse industries globally.

Key Products:

- Cutting Tools

- Tool and Cutter Grinders

- Cutting Tool Resharpening Services

Reasons for Recommendation:

- Wide variety of products.

- Its dependable partnership with companies is based on its dedication to client satisfaction.

- Seeking advanced gear manufacturing solutions.

6.Liebherr

Profile: Liebherr is a German manufacturer known for its expertise in construction machinery, mining equipment, and gear technology. The company offers innovative solutions for gear manufacturing and precision engineering.

Key Products:

- Construction Machinery

- Mining Equipment

- Aerospace and Transportation

Reasons for Recommendation:

- Acknowledged for its high standard of quality.

- Businesses favor it due to its advanced technology and innovative features.

- Trying to find cutting-edge methods for gear grinding.

7.Kanzaki

Profile: Kanzaki is a Japanese manufacturer specializing in gear manufacturing machinery and equipment. With a focus on precision and reliability, the company serves various industries globally.

Key Products:

- Reduction Gears

- Hydrostatic Transmissions

- Hydraulic Clutches

- Mechanical Clutches

Reasons for Recommendation:

- Dedicated to excellence and new ideas.

- Companies trust it as a partner because of its positive feedback from clients.

- Dependable solutions for gear grinding.

8.Emag AG

Profile: Emag AG is a German manufacturer specializing in machine tools and production systems. With a focus on innovation and efficiency, the company offers solutions for gear manufacturing and automotive industries.

Key Products:

- Turning Machines

- Grinding Machines

- Vertical Turning Machines

Reasons for Recommendation:

- Companies seeking superior gear grinding solutions often choose it due to its technical knowledge.

- dedication to customer satisfaction.

9.Mitsubishi Heavy

Mitsubishi Heavy Industries (MHI) Group stands as a house of excellence in CNC gear shaving manufacturing. It is a top industrial group involved in energy, logistics, infrastructure, machinery, aerospace, and defense.

For 80 years, Mitsubishi Heavy Industries Machine Tool has provided various industries with gear-hobbing, chamfering/deburring, skiving, grinding, and gear-shaving machines. MHI Group uses advanced technology and vast experience to offer innovative solutions for a carbon-neutral world, improved quality of life, and a safer planet.

Mitsubishi's CNC Gear Shaving unit is famous for its robust build, precision, and flexibility. They aim to use reliable manufacturing technology to deliver quality products and create a better future.

Key Products:

Printing machinery,

chemical plants,

and air-conditioning & refrigeration systems

Reasons For Recommendation:

- Trusted for high-quality products and advanced technology

- Renowned for reliability and durability

- Exceptional customer service and support

- Globally recognized for innovation and engineering excellence

10.Helios

Profile: Helios is an American manufacturer specializing in gear-cutting tools and gear-grinding solutions. With a focus on quality and innovation, the company serves various industries worldwide.

Key Products:

- Gear grinding tools

- Gear cutting machines

- Automation solutions

Reasons for Recommendation:

- Trustworthy options for gear grinding

- Dedication to customer satisfaction.

- Technological excellence makes it a preferred choice for companies.

When looking to invest in CNC gear grinder machines for their manufacturing processes, companies may make educated judgments by examining these top manufacturers and their services. Because each of these companies offers something unique, customers can trust them to provide reliable, high-quality gear-grinding solutions tailored to their needs.

Conclusion

Finally, the world's leading 10 CNC gear grinder machine brand manufacturers showcase their unmatched precision grinding skills and innovative mindset. Due to their innovative processes, commitment to quality, and happy customers, they have risen to the top of their industry. The worldwide reach and dedication to the improvement of these manufacturers greatly affect the future of gear production on a global scale. The reason is, that they have a worldwide presence.

Don't forget to share this post!

Related Products

CONTACT US

Tell us your raw material and working details to get quotations within 24 hours.

WhatsApp Us: +86 159 27 555863

Want the best price & newest metal working machinery buying guide,tips and trends sent straightly to your box?Sign up for Armpro's monthly newsletter,we're free for your consultation and Offer you the most suitable working solutions!

The Buyer's Guide

- Tapping Machine: The Ultimate Buying Guide in 2021

- Electric Tapping Machines:the Ultimate Buying Guide in 2021

- Drilling Machine: The Ultimate Buying Guide in 2021

- Grinding Machine:The Ultimate Buying Guide in 2021

- Metal Band Saw Machine :The Complete Buying Guide in 2021

- Pneumatic Tapping Machine:The Complete Importing Guide in 2021

- Bench Tapping Machine:The Complete Buying Guide in 2021

- CNC Tapping Machine:The Complete Buying Guide In 2021

- Magnetic Base Drill Machine:The Ultimate Buying Guide in 2021

- Drilling And Tapping Machine:The Complete Buying Guide in 2021

Most Popular

Tell us your material or budget,we'll reply you ASAP within 24 hours