UNC Thread size chart

UNC - Unified Coarse Thread

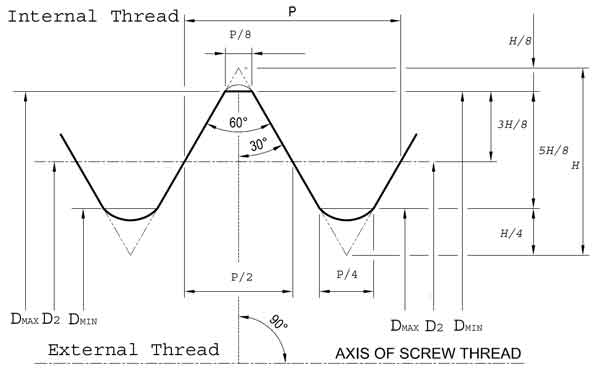

Presently in the manufacturing industry, there are a variety of choices based on types as well as sizes out of which choices can be made according to the circumstance. however, there are specific threads that are usually used based on the particular applications. The UTS (Unites Thread Standard) is a standard which defines the standard for threads and forms. they also define the allowances, designations and tolerances for screw threads that are commonly used throughout several industries. UTS or United Thread Standard is considered as the main standard for nuts and bolts, as well as many more types of threaded fasteners that can be seen to be used widely in countries where manufacturing processes take place. Although United Thread Standards have the same 60-degree profile similar to ISO metric screw threads, they show a slight difference in the characteristic dimension. That is, each UTS thread has an outer diameter and pitch that has been constructed based on an inch fraction rather than from a millimetre (mm) value. Specific standards like UTS (United Thread Standard) are used in order to attain order and near perfection in the applications.

UNC, also known as Unified National Coarse Thread is a standard that is used for screw threads that are used for nuts and bolts. The usage of these threads can widely be seen around the United States.

Unified Coarse Thread system belongs to a series of standards that were initially developed to make sure that there is compatibility and interchangeability in threaded fasteners. Currently the UTS threads and their designations and sizes are under the control and management of the ASME/ANSI in the United States of America.

1. What is Characteristics of Unified National Coarse Threads

Out of the two Unified Thread Standards (UTS), UNC threads are the most commonly used, the other being UNF (United National Fine Threads). UNC threads have specific characteristics that make them more suitable for the applications they are used for. Some such features are as follows.

Unified Coarse Threads are less likely to cross-thread between themselves cue to their texture.

UNC threads enable faster assembly and disassembly of fittings. They are used in mass production due to this feature.

UNC threads enable a thicker plating and coating of fittings as they have large thread allowances.

When compared to UNF threads (fine threads), UNC threads have a fewer number of threads per distance.

UNC threads are subjected to a classification system which helps to make it easy to manufacture them. The thread class indicates the range of pitch diameter for any specific range of thread. These classes are specified according to their tolerances and are called the United Screw Thread Standard Series. UNC can be found in five different classes. They are as follows:

- Class 1 UNC threads are used for applications which require a liberal tolerance is required in order to ensure an easy assembly. This is common to instances where slightly nicked threads are used. They have a loosely fitting set of threads that are used in easy assembly points or in a dirty environment.

- Class 2 UNC threads are the types of UNC threads are the most commonly used class for general-purpose applications. These UNC threads are designed and manufactured to maximise the strength in relation to machine practice.

- Class 3 UNC threads are used in applications where it is important to use close fit and accurate thread elements.

- Class 4 UNC threads are manufactured to use in a closer fit than a Class 3 UNC thread.

- Class 5 UNC threads are designed nd manufactured to be used on item,s like spring shackles in automobiles. Therefore, class 5 UNC threads are not manufactured with loose threads,

UNC threads can be identified as either internal or external threads. The letter suffix along with their class indicates whether they are internal or external threads. The letter suffix of either ‘A’ or ‘B’ is used for this purpose, where ‘A’ indicates external threads, meanwhile ‘B’ indicates internal threads. Thereby, classes 1A, 2A, and 3A indicate external threads, while Classes 1B, 2B, and 3B apply to internal threads.

The thread pitch is the distance between the threads that is indicated in millimetres. Usually, smaller fasteners have finer threads, which means they have a relatively lower thread pitch. The typical designation of a UNC thread is ¼” x 20 Unified National Coarse Thread.

2. What is Applications of UNC - United National Coarse Threads?

UNC (Unified National Coarse Threads) are widely used in various applications throughout many industries.

some common applications of UNC threads are as follows:

- Equipment Manufacturing

- Aerospace industry

- Furniture Industry

- Production of consumer goods

- House Interior improvement machinery

- Manufacturing DIY tools

- Electronic equipment

- Electrical equipment

- Gas and Oil industry

3. What is UNC - Unified Coarse Threads Size Chart

The UNC threads that have sizes below are given a number that is defined using the standard. This type of smaller-sized thread is commonly referred to using numbers and pitch. This can be put out as 10-24 which would be UNC No. 10 or 10-32 UNF No. 10.

It is important to note thast the basic profile of all the UTS threads, may it be UNC or UNF, is similar to that of the ISO Metric Scrrew thread standards. The only difference in vaalues is exhibited in the Dmaj (outer diameter) and P (pitch).

Below given is a UNC size chart according to the ANSI B1.1 size chart.

| Thread | Major Diameter | Thread Per Inch | Pitch Diameter | Minor Diameter Male Thread |

Minor Diameter Female Thread |

|---|---|---|---|---|---|

| 1 | 0.0730 | 64 | 0.0629 | 0.0544 | 0.0561 |

| 2 | 0.0860 | 56 | 0.0744 | 0.0648 | 0.0667 |

| 3 | 0.0990 | 48 | 0.0855 | 0.0741 | 0.0764 |

| 4 | 0.1120 | 40 | 0.0958 | 0.0822 | 0.0849 |

| 5 | 0.1250 | 40 | 0.1088 | 0.0952 | 0.0979 |

| 6 | 0.1380 | 32 | 0.1177 | 0.1008 | 0.1042 |

| 8 | 0.1640 | 32 | 0.1437 | 0.1268 | 0.1302 |

| 10 | 0.1900 | 24 | 0.1629 | 0.1404 | 0.1449 |

| 12 | 0.2160 | 24 | 0.1889 | 0.1664 | 0.1709 |

| 1/4 | 0.2500 | 20 | 0.2175 | 0.1905 | 0.1959 |

| 5/16 | 0.3125 | 18 | 0.2764 | 0.2464 | 0.2524 |

| 3/8 | 0.3750 | 16 | 0.3344 | 0.3005 | 0.3073 |

| 7/16 | 0.4375 | 14 | 0.3911 | 0.3525 | 0.3602 |

| 1/2 | 0.5000 | 13 | 0.4500 | 0.4084 | 0.4167 |

| 9/16 | 0.5625 | 12 | 0.5084 | 0.4633 | 0.4723 |

| 5/8 | 0.6250 | 11 | 0.5660 | 0.5168 | 0.5266 |

| 3/4 | 0.7500 | 10 | 0.6850 | 0.6309 | 0.6417 |

| 7/8 | 0.8750 | 9 | 0.8028 | 0.7427 | 0.7547 |

| 1 | 1.0000 | 8 | 0.9188 | 0.8512 | 0.8647 |

| 1-1/8 | 1.1250 | 7 | 1.0322 | 0.9549 | 0.9704 |

| 1 1/4 | 1.2500 | 7 | 1.1572 | 1.0799 | 1.0954 |

| 1-3/8 | 1.3750 | 6 | 1.2667 | 1.1766 | 1.1946 |

| 1 1/2 | 1.5000 | 6 | 1.3917 | 1.3016 | 1.3196 |

| 1 3/4 | 1.7500 | 5 | 1.6201 | 1.5119 | 1.5335 |

| 2 | 2.0000 | 4.5 | 1.8557 | 1.7353 | 1.7594 |

| 2 1/4 | 2.2500 | 4.5 | 2.1057 | 1.9853 | 2.0094 |

| 2 1/2 | 2.5000 | 4 | 2.3376 | 2.2023 | 2.2294 |

| 2 3/4 | 2.7500 | 4 | 2.5876 | 2.4523 | 2.4794 |

| 3 | 3.0000 | 4 | 2.8376 | 2.7023 | 2.7294 |

| 3 1/4 | 3.2500 | 4 | 3.0876 | 2.9523 | 2.9794 |

| 3 1/2 | 3.5000 | 4 | 3.3376 | 3.2023 | 3.2294 |

| 3 3/4 | 3.7500 | 4 | 3.5876 | 3.4523 | 3.4794 |

| 4 | 4.0000 | 4 | 3.8376 | 3.7023 | 3.7294 |

4. Conclusion

UTS or United Thread Standard is a standard widely used in the United States and Canada in order to assign designations and allowances to nuts and bolts that are used in manufacturing and industrial applications. The UTS can be divided into two classifications, i.e. the UNC (United National Coarse Thread) and UNF (United National Fine Thread). UNC differs from UNF due to the coarse threads it possesses.

UNC is commonly used in various applications due to their ease of use and therefore has a wide range of applications. They are used in many industries like manufacturing, oil and gas industry as well as hydraulic systems. It is important to maintain a standard like UTS to ensure smooth functioning of machinery and equipment.

Don't forget to share this post!

Related Products

CONTACT US

Tell us your raw material and working details to get quotations within 24 hours.

WhatsApp Us: +86 159 27 555863

Want the best price & newest metal working machinery buying guide,tips and trends sent straightly to your box?Sign up for Armpro's monthly newsletter,we're free for your consultation and Offer you the most suitable working solutions!

The Buyer's Guide

- Tapping Machine: The Ultimate Buying Guide in 2021

- Electric Tapping Machines:the Ultimate Buying Guide in 2021

- Drilling Machine: The Ultimate Buying Guide in 2021

- Grinding Machine:The Ultimate Buying Guide in 2021

- Metal Band Saw Machine :The Complete Buying Guide in 2021

- Pneumatic Tapping Machine:The Complete Importing Guide in 2021

- Bench Tapping Machine:The Complete Buying Guide in 2021

- CNC Tapping Machine:The Complete Buying Guide In 2021

- Magnetic Base Drill Machine:The Ultimate Buying Guide in 2021

- Drilling And Tapping Machine:The Complete Buying Guide in 2021

Most Popular

Tell us your material or budget,we'll reply you ASAP within 24 hours