UNF Thread size chart

UTS (Unified Thread Standard) is a standard used around the United States and Canada that is used as an identification standard for screws, bolts, and nuts. As there are a number of different types of threads, the UTS standard was developed in order to be used as a specific standard to differentiate among the various types of threads. Different types and series of screw threads belong to this standard.

They are UNC (Unified National Coarse Threads), UNF (Unified National Fine Threads), UNEF (United National Extra Fine Pitch Threads) and UNS (Unified Special Threads. These standards are applied based on the specific screws, bolts and nuts.

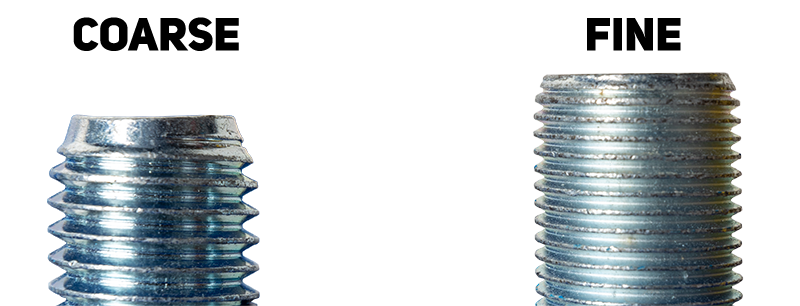

The UNF and UNC are defined based on the number of threads per inch (TPI). while both types are generally used for fastening they are applied in different fields as their varying characteristics provide differentiated facilities.

For instance, due to the higher strength possessed by the UNC thread, they are used in applications that require high tensile strength. Meanwhile, UNF threads are used for sealing due to their reliable self-sealing structure.

1. What is Characteristics of UNF - Unified National Fine Threads

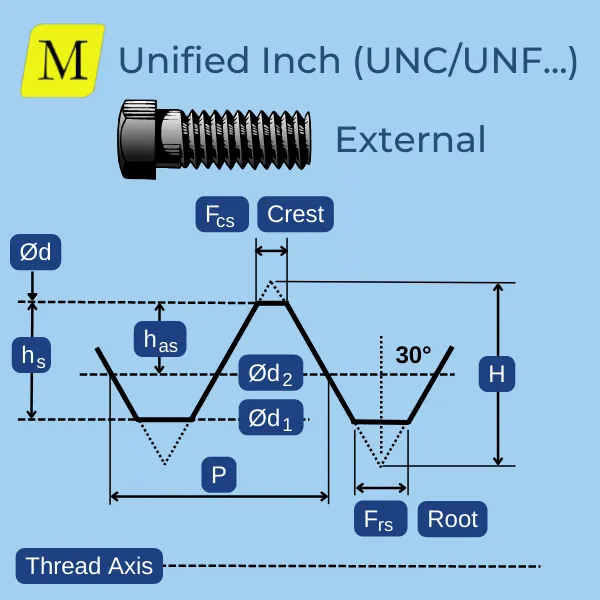

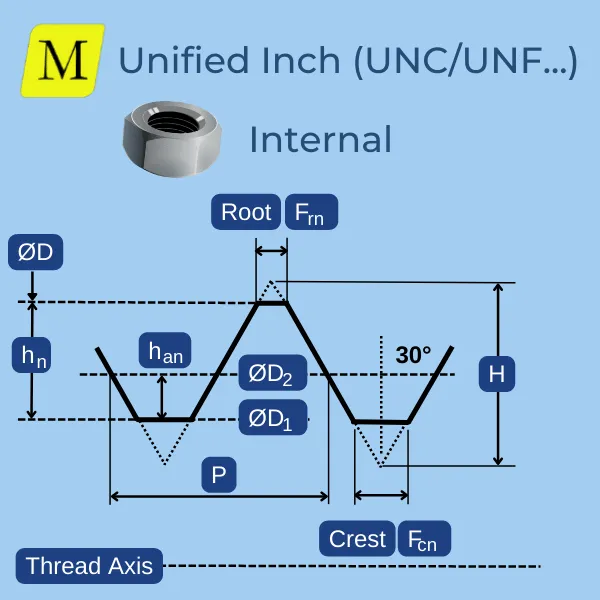

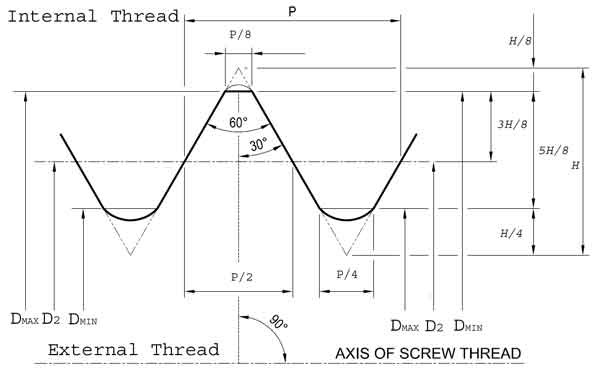

UNF threads, unlike UNC threads, have a finer pitch. These types of threads are used in applications which require high tensile strength and in applications where the threaded parts are relatively thin. Some similarities can be found between UNC and UNF threads. Both UNC and UNF threads in male and female versions are parallel to each other. Also, the flank angles of both UNC and UNF threads are 60 degrees. The typical designation of a UNF thread is ½” x 20. The standard of UNF threads is managed by the ANSI/ASME B1.1 Unified National Thread.

The UNF thread has a smaller space occupation size and better self-locking performance when compared to a UNC thread. A number of different fine thread types can be found to make a series of fine threads - MF/UNF/UNRF. these fine threads are not generally used in applications which require a large stress. Usually, fine threads are used in applications like positioning and fixing adjustments, and similar instances where high fastener strength is required. Also, fine threads are used in applications where fine adjustments are done. for instance, these threads are used in tools like micrometers and to fix lenses in various optical instruments, and battery covers of metal-shelled flashlights.

Although with its specified advantages, has its disadvantages too. As the fine thread is comparatively smaller in height and size, it can be prone to displacement and disorder very easily. Also, it should be regularly cleaned up as the burr is important during assembly. moreover, it can be difficult to remove the threads in case of any emergency, due to their small size.

UNF threads have a smaller pitch and consist of more teeth screwed in the same thread length. This feature is important as it can prevent fluid leakage, and is made use of in applications where sealing is needed. As UNF threads have a smaller cross-section size of each tooth, with a large number of teeth, they are generally replaced with UNC threads for applications that require bearing a large tensile force and impact force. However, compared to the UNF threads, UNC threads have a batter interchangeability and higher measure of strength, while also possessing greater tolerances and thereby handling manufacturing in a better way than UNF threads.

However, based on their different characteristics, both UNC and UNF threads have different uses and are applied in a wide range of applications.

2. What is the Applications of UNF threads

Although the usage of UNC threads and UNF threads pretty much give the same outcomes, fine threads have a better prevention of loosening than UNC threads. As the UNF threads have a smaller helix angle than the UNC threads, they are more prone to the self-locking feature of the thread. Due to this, the thread would remain tight and not loosen very easily. Making use of this feature, UNF threads are generally used for thin-walled parts and places which require higher anti-vibration.

Fine threads are used in a wide range of applications throughout many industries. The specialised structure of these threads makes them easy to use and applicable in a general and common way. These are some common instances and industries which make use of UNF threads.

- Hydraulic systems

- Pneumatic systems

- Telecommunications industry

- Medical devices manufacturing

- Aerospace industry

- Automotive industry

- High-performance machinery

- Control systems

Although other types of threads are also used in these industries, there are some specific applications where UNF threads provide the best reliability.

3. What is the size chart for UNF - Unified National Fine Threads ?

As there are different sizes of UNF threads, the applications of these threads may vary based on their specifications as well.

therefore, it is important to find out which is the most suitable UNF thread for your specific requirement in order to obtain the most reliable outcome.

The following table offers a quick guide on the available UNF thread sizes where you can refer to the metric thread dimensions and specifications to determine the required UNF thread.

The table below shows the types of screw threads, sizes, and specifications of Unified Fine (UNF) threads.

| Thread | Major Diameter | Thread per Inch | Pitch Diameter | Minor Diameter Male Thread | Minor Diameter Female Thread |

|---|---|---|---|---|---|

| 0 | 0.0600 | 80 | 0.0519 | 0.0451 | 0.0465 |

| 1 | 0.0730 | 72 | 0.0640 | 0.0565 | 0.0580 |

| 2 | 0.0860 | 64 | 0.0759 | 0.0674 | 0.0691 |

| 3 | 0.0990 | 56 | 0.0874 | 0.0778 | 0.0797 |

| 4 | 0.1120 | 48 | 0.0985 | 0.0871 | 0.0894 |

| 5 | 0.1250 | 44 | 0.1102 | 0.0979 | 0.1004 |

| 6 | 0.1380 | 40 | 0.1218 | 0.1082 | 0.1109 |

| 8 | 0.1640 | 36 | 0.1460 | 0.1309 | 0.1339 |

| 10 | 0.1900 | 32 | 0.1697 | 0.1528 | 0.1562 |

| 12 | 0.2160 | 28 | 0.1928 | 0.1734 | 0.1773 |

| 1/4 | 0.2500 | 28 | 0.2268 | 0.2074 | 0.2113 |

| 5/16 | 0.3125 | 24 | 0.2854 | 0.2629 | 0.2674 |

| 3/8 | 0.3750 | 24 | 0.3479 | 0.3254 | 0.3299 |

| 7/16 | 0.4375 | 20 | 0.4050 | 0.3780 | 0.3834 |

| 1/2 | 0.5000 | 20 | 0.4675 | 0.4405 | 0.4459 |

| 9/16 | 0.5625 | 18 | 0.5264 | 0.4964 | 0.5024 |

| 5/8 | 0.6250 | 18 | 0.5889 | 0.5589 | 0.5649 |

| 3/4 | 0.7500 | 16 | 0.7094 | 0.6763 | 0.6823 |

| 7/8 | 0.8750 | 14 | 0.8286 | 0.7900 | 0.7977 |

| 1 | 1.0000 | 12 | 0.9459 | 0.9001 | 0.9098 |

| 1 1/8 | 1.1250 | 12 | 1.0709 | 1.0258 | 1.0348 |

| 1 1/4 | 1.2500 | 12 | 1.1959 | 1.1508 | 1.1598 |

| 1 3/8 | 1.3750 | 12 | 1.3209 | 1.2758 | 1.2848 |

| 1 1/2 | 1.5000 | 12 | 1.4459 | 1.4008 | 1.4098 |

4. Conclusion

The Unified Thread Standard is a standardization developed in order to maintain the reliability and consistency in nuts and bolts used for fastening and other fittings. Many thread series are categorised under the UTS standard and are widely used around United States and Canada. UNC, UNF and UNEF are some such common standards.

Although both UNC and UNF are widely used for fastening applications, due to their structural differences, they have specific applications that increase their specialised applications. The significant feature of UNified Fine Thread us that they have a finer thread than the unified coarse thread series. Hydraulic systems and pneumatic systems, manufacturing industries, medical device manufacturers and automotive industry are some instances where UNF threads are widely used.

Due to thei ability to self-lock efficiently, they are usually used in applications where tightened fastening is required. As there are a variety of sizes to choose from, a UNF thread size chart will offer a perfect guide to choose the most suitable thread needed for your specific requirements.

Don't forget to share this post!

Related Products

CONTACT US

Tell us your raw material and working details to get quotations within 24 hours.

WhatsApp Us: +86 159 27 555863

Want the best price & newest metal working machinery buying guide,tips and trends sent straightly to your box?Sign up for Armpro's monthly newsletter,we're free for your consultation and Offer you the most suitable working solutions!

The Buyer's Guide

- Tapping Machine: The Ultimate Buying Guide in 2021

- Electric Tapping Machines:the Ultimate Buying Guide in 2021

- Drilling Machine: The Ultimate Buying Guide in 2021

- Grinding Machine:The Ultimate Buying Guide in 2021

- Metal Band Saw Machine :The Complete Buying Guide in 2021

- Pneumatic Tapping Machine:The Complete Importing Guide in 2021

- Bench Tapping Machine:The Complete Buying Guide in 2021

- CNC Tapping Machine:The Complete Buying Guide In 2021

- Magnetic Base Drill Machine:The Ultimate Buying Guide in 2021

- Drilling And Tapping Machine:The Complete Buying Guide in 2021

Most Popular

Tell us your material or budget,we'll reply you ASAP within 24 hours