ASTM A193 Standard Bolts Size Chart

Bolts and nuts are tools used in order to connect two or more mechanical parts with each other. ASTM A193 bolts are used to connect ferritic and austenitic stainless steel efficiently. There are many types of A193 bolts such as A193M Hex Head Bolt, A193 Eye Bolt, and ASME SA193M Lag Bolt. The ASTM A193 Head bolts are popular due to their advantageous properties like enhanced corrosion resistance and chemical composition. The ASTM A193 Eye Bolts have reached popularity due to their physical as well as mechanical properties.

There are numerous grades within the ASTM A193 specification. Each grade differs from one another based on its unique chemical compositions, strength requirements and differences between many of the grades.

1. What are the ASTM A193 B7 Bolts and nut Specifications?

ASTM A193 B7 Bolts contain the requirements that are needed for bolting high tensile alloy steel material to be used in high-temperature or high-pressure environments. The standard definition includes the typical chemical composition, mechanical properties, hardness requirements, heat treatment, product marking, certification and more requirements.

When ASTM A193 Grade B7 bolts are considered, it is heat-treated with chromium-molybdenum low-alloy steel and has a minimum tensile strength requirement of 125 ksi and a yield of 105 ksi. It has a maximum hardness of 35HRC. A193 B7 bolts are available in a size range from M6 to M180 and imperial sizes from ¼ to 7 inches in diameter.

2. What are the Types of A193 B7 Bolts?

There are several types of ASTM A193 bolts in the market. They have slight to significant differences among each of them. However as all of them are used for the same purpose, it is important to at least know their names among the most used A193 bolts.

Mainly the ASTM A193 Bolts are classified under twelve categories. They are:

Studs, Double-end studs, Hex bolts, Socket heads, Threaded rods, CSK screws, Heavy hex bolts, Socket set screws, Eye bolts, Round bars, Anchor bolts and U bolts.

- These types of A193 bolts are further categorised based on their usage. This would make it easier to choose the best option that suits your requirement out of all the bolts. Some types of ASTM A193 Bolts are as follows:

- ASTM A193 Bolts

- ASM A193 Material

- ASTM A193 Fastener

- SA193 Hex Bolt

- A193M Heavy Hex Bolt

- SA193 Carriage Bolt

- A193 Hex Head Bolt

- ASME SA193 U-bolts

- ASME SA193 U -bolts

- A193 Eye bolts

- A193 Square Bolt

- ASTM Machine Bolt

- ASME SA193M Flange Bolt

- SA193 Heavy Hex Head Bolt

3. What are the manufacturing Standards of A193 B7 Bolts?

A193 Grade B7 bolts are used in many prominent manufacturing processes. Therefore it is important to maintain the integrity and high standards of the product. As the bolts will be used in the basic assembly of any manufactured material they would belong to the underlying architecture of the material and thereby hold a high responsibility of keeping the material together.

Due to these matters, when manufacturing ASTM A193 bolts, high standards are given attention. The below chart shows the standards assigned by DIN, ISO, ASME and UNI for each type of ASTM A193 bolt product based on their value.

4. What are the ASTM A193 Bolt B7 Characteristics?

ASTM A193 Grade B7 has a special elemental chemical composition that makes it strong and durable. The ASTM A193 B7 bolts contain Carbon, Phosphorus, Sulfur, Manganese, Silicon, Chromium and Molybdenum.

Chemical Analysis chart of ASTM A193 B7m Bolts

| Element | B7 (AISI 4140) |

|---|---|

| Carbon | 0.38 - 0.48% |

| Manganese | 0.75 - 1.00% |

| Phosphorus, max | 0.035% |

| Sulfur, max | 0.040% |

| Silicon | 0.15 - 0.35% |

| Chromium | 0.80 - 1.10% |

| Nickel | |

| Molybdenum | 0.15 - 0.25% |

The A193 B7 bolts are heat treated by quenching them in a liquid medium and then tempering them. The material for A193 Grade B7 can be heat-treated using the furnace, induction or even using the electrical resistance method.

The heat treating guide for ASTM A193 Grade B7 bolts based on the diameter is given below. Here the diameter is measured in metric sizes.

The heat treating guide for ASTM A193 Grade B7 bolts based on the diameter is given below. Here the diameter is measured in inches.

Most Selling types of ASTM A193 b7 Stud Bolts

| ASTM A193 Grand B7 Stud Bolt | Stainless Steel B7 Threaded Rod |

| ASTM A 193 B7 Stud Bolt | ASTM A 193 Eye Bolt |

| Stainless Steel B7 Studs | ASTM A 193 B7 Lag Bolt |

| ASTM A193 B7 Stud Bolts | B7 Grub Screw |

| ASTM A193 J Bolt | ASTM A193 B7 Anchor Bolt |

| B7 Hanger Bolt | A193 B7 Hex Nut |

| SS B7 Plow Bolt | ASTM A193 B7 Stud Bolts |

| ASTM A193 stud bolts | SA193 Nuts |

| ASTM A 193 B7 Studs | B7 Shoulder Bolt |

| B7 Stainless Steel Stud bolts | Stainless Steel B7 Draw Bolt |

| ASTM A 193 Tie Rod | SS B7 Step Bolt |

| ASTM A 193 B7 Heavy Hex Bolts | ISO Approved ASTM A193 U Bolts |

4. What is ASTM A193 Grade B7 Torque Chart?

Torque Chart For ASTM A193 Grade B7 Studs In Ft./Lbs.

| Bolt Diameter | Nut Size | Moly Lube | Nickel Lube | Copper Lube | Machine Oil | Dry |

|---|---|---|---|---|---|---|

| u=0.085 | u=0.110 | u=0.100 | u=0.160 | u=0.400 | ||

| 3/4" | 1-1/4" | 208 | 342 | 314 | 448 | 1118 |

| 7/8" | 1-7/16" | 330 | 544 | 500 | 716 | 1786 |

| 1" | 1-5/8" | 490 | 810 | 746 | 1066 | 2664 |

| 1-1/8" | 1-13/16" | 702 | 1170 | 1076 | 1544 | 3888 |

| 1-1/4" | 2" | 966 | 1622 | 1492 | 2150 | 5440 |

| 1-3/8" | 2-3/16" | 1288 | 2180 | 2000 | 2894 | 7356 |

| 1-1/2" | 2-3/8" | 1674 | 2850 | 2614 | 3792 | 9274 |

| 1-5/8" | 2-9/16" | 2142 | 3668 | 3364 | 4890 | 12520 |

| 1-3/4" | 2-3/4" | 2676 | 4602 | 4218 | 6144 | 15776 |

| 1-7/8" | 2-15/16" | 3292 | 5682 | 5204 | 7596 | 19550 |

| 2" | 3-1/8" | 3994 | 6920 | 6334 | 9260 | 23884 |

| 2-1/8" | N/A | 4790 | 8324 | 7618 | 11150 | 28816 |

| 2-1/4" | 3-1/2" | 5686 | 9906 | 9068 | 13282 | 34382 |

| 2-3/8" | N/A | 6686 | 11676 | 10678 | 15668 | 40620 |

| 2-1/2" | 3-7/8" | 7796 | 13646 | 12476 | 18324 | 47536 |

| 2-3/4" | 4-1/4" | 9382 | 16488 | 15066 | 22170 | 57692 |

| 3" | 4-5/8" | 13974 | 21464 | 19606 | 28894 | 75340 |

| 3-1/4" | 5" | 15470 | 27352 | 24976 | 36856 | 96258 |

| 3-1/2" | 5-3/8" | 19312 | 34226 | 31244 | 46158 | 120730 |

| 3-3/4" | 5-3/4" | 23742 | 42168 | 38482 | 56906 | 149032 |

| 4" | 6-1/8" | 27262 | 48590 | 44324 | 65652 | 172292 |

| 4-1/4" | 6-1/2" | 28802 | 51248 | 46758 | 69206 | 181440 |

| 4-1/2" | 6-7/8" | 32348 | 57742 | 52664 | 78058 | 205026 |

ASTM A193 B7 Bolts And Nuts Tensile Strength / Hardness Chart

| Diameter | Tensile Strength Min KSI | Yield Strength 0.2% Offset KSI | Elongation in 4D, Min, % | Reduction of Area Min, % | Hardness Max Brinell | Hardness Max Rockwell | |

|---|---|---|---|---|---|---|---|

| B7 | to 2-1/2" | 125 | 105 | 16 | 50 | - | C35 |

| over 2-1/2 to 4" | 115 | 95 | 16 | 50 | - | C35 | |

| Classes 1 and 1D: B8, B8M, B8P, B8LN, B8ML | ALL | 75 | 30 | 30 | 50 | 223 | B96 |

| Class 1: B8C, B8T | ALL | 75 | 30 | 30 | 50 | 223 | B96 |

| Class 1A: B8A, B8CA, B8MA, B8PA, B8TA, B8LNA, B8MLNA, B8NA, B8MNA, B8MLCuNA | ALL | 75 | 30 | 30 | 50 | 192 | B90 |

| Classes 1B & 1D: B8N, B8MN, B8MLCuN | ALL | 80 | 35 | 30 | 40 | 223 | B96 |

| Class 1C and 1D: B8R | ALL | 100 | 55 | 35 | 55 | 271 | C28 |

| Class 1C: B8RA | ALL | 100 | 55 | 35 | 55 | 271 | C28 |

| Classes 1C and 1D: B8S | ALL | 95 | 50 | 35 | 55 | 271 | C28 |

| Classes 1C: B8SA | ALL | 95 | 50 | 35 | 55 | 271 | C28 |

| Class 2: B8, B8C, B8P, B8T, B8N | to 3/4" | 125 | 100 | 12 | 35 | 321 | C35 |

| over 3/4" to 1" | 115 | 80 | 15 | 35 | 321 | C35 | |

| over 1" to 1-1/4" | 105 | 65 | 20 | 45 | 321 | C35 | |

| over 1-1/4 to 1-1/2" incl | 100 | 50 | 28 | 45 | 321 | C35 | |

| Class 2 B8M, B8MN, B8MLCuN | to 3/4" | 110 | 96 | 15 | 45 | 321 | C35 |

| over 3/4" to 1" | 100 | 80 | 20 | 45 | 321 | C35 | |

| over 1" to 1-1/4" | 95 | 65 | 25 | 45 | 321 | C35 | |

| over 1-1/4 to 1-1/2" incl | 90 | 50 | 30 | 45 | 321 | C35 | |

| Class 2B: B8, B8M2 | to 2" incl | 95 | 75 | 25 | 40 | 321 | C35 |

| over 2" to 2-1/2" incl | 90 | 65 | 30 | 40 | 321 | C35 | |

| over 2-1/2 " to 3" incl | 80 | 55 | 30 | 40 | 321 | C35 | |

| Class 2C: B8M3 | to 2" incl | 85 | 65 | 30 | 60 | 321 | C35 |

| over2" | 85 | 60 | 30 | 60 | 321 | C35 |

5. What is the Size Chart of ASTM A193 B7 Bolts?

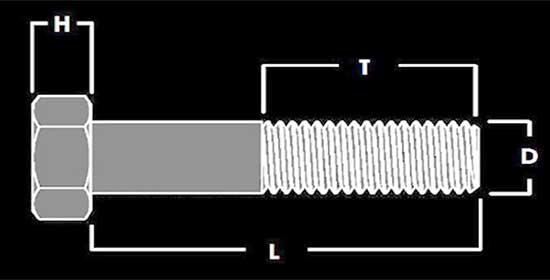

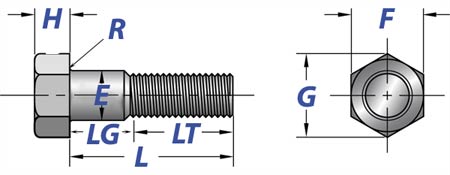

Several dimensions are used to measure the size of an ASTM A193 B7 bolt. The basic dimension out of them is the diameter of the screw (D). Then, along with it, the diameter of the body (D), length across the flats (F), length across the corners ©, the height of the head (H) and length of the thread (T) is measured in order to determine the size of the bolt.

| Diameter (D) | Body Diameter (D) | Across the Flats (F) | Across the Corners © | Head Height (H) | Thread Lengths (T) | |||||

| MAX | MIN | MAX | MIN | MAX | MIN | MAX | MIN | < 6” | > 6” | |

| 1/2 | 0.515 | 0.482 | 0.875 | 0.85 | 1.01 | 0.969 | 0.364 | 0.302 | 1.25 | 1.5 |

| 5/8 | 0.642 | 0.605 | 1.062 | 1.031 | 1.227 | 1.175 | 0.444 | 0.378 | 1.5 | 1.75 |

| 3/4 | 0.768 | 0.729 | 1.25 | 1.212 | 1.443 | 1.383 | 0.524 | 0.455 | 1.75 | 2 |

| 7/8 | 0.895 | 0.852 | 1.438 | 1.394 | 1.66 | 1.589 | 0.604 | 0.531 | 2 | 2.25 |

| 1 | 1.022 | 0.976 | 1.625 | 1.575 | 1.876 | 1.796 | 0.7 | 0.591 | 2.25 | 2.5 |

| 1 1/8 | 1.149 | 1.098 | 1.812 | 1.756 | 2.093 | 2.002 | 0.78 | 0.658 | 2.5 | 2.75 |

| 1 1/4 | 1.277 | 1.223 | 2 | 1.938 | 2.309 | 2.209 | 0.876 | 0.749 | 2.75 | 3 |

| 1 3/8 | 1.404 | 1.345 | 2.188 | 2.119 | 2.526 | 2.416 | 0.94 | 0.81 | 3 | 3.25 |

| 1 1/2 | 1.531 | 1.47 | 2.375 | 2.3 | 2.742 | 2.622 | 1.036 | 0.902 | 3.25 | 3.5 |

| 1 3/4 | 1.785 | 1.716 | 2.75 | 2.662 | 3.175 | 3.035 | 1.196 | 1.054 | 3.75 | 4 |

| 2 | 2.039 | 1.964 | 3.125 | 3.025 | 3.608 | 3.449 | 1.388 | 1.175 | 4.25 | 4.5 |

| 2 1/4 | 2.305 | 2.214 | 3.5 | 3.388 | 4.041 | 3.862 | 1.548 | 1.327 | 4.75 | 5 |

| 2 1/2 | 2.559 | 2.461 | 3.875 | 3.75 | 4.474 | 4.275 | 1.708 | 1.479 | 5.25 | 5.5 |

| 2 3/4 | 2.827 | 2.711 | 4.25 | 4.112 | 4.907 | 4.688 | 1.869 | 1.632 | 5.75 | 6 |

| 3 | 3.081 | 2.961 | 4.625 | 4.475 | 5.34 | 5.102 | 2.06 | 1.815 | 6.25 | 6.5 |

As the ASTM A193 bolts come in a range of sizes, it might be quite a challenge to choose the best one that suits your requirement. However, the below chart can be used as a trusted guide to specify the bolts you need to get.

SA 193 Heavy Hex Bolt Dimension Standards size chart

| Diameter (D) | Body Diameter (D) | Across the Flats (F) | Across the Corners © | Head Height (H) | Thread Lengths (T) | |||||

| MAX | MIN | MAX | MIN | MAX | MIN | MAX | MIN | < 6” | > 6” | |

| 2 | 2.039 | 1.964 | 3.125 | 3.025 | 3.608 | 3.449 | 1.388 | 1.175 | 4.25 | 4.5 |

| 1 1/4 | 1.277 | 1.223 | 2 | 1.938 | 2.309 | 2.209 | 0.876 | 0.749 | 2.75 | 3 |

| 5月8日 | 0.642 | 0.605 | 1.062 | 1.031 | 1.227 | 1.175 | 0.444 | 0.378 | 1.5 | 1.75 |

| 3月4日 | 0.768 | 0.729 | 1.25 | 1.212 | 1.443 | 1.383 | 0.524 | 0.455 | 1.75 | 2 |

| 7月8日 | 0.895 | 0.852 | 1.438 | 1.394 | 1.66 | 1.589 | 0.604 | 0.531 | 2 | 2.25 |

| 1月2日 | 0.515 | 0.482 | 0.875 | 0.85 | 1.01 | 0.969 | 0.364 | 0.302 | 1.25 | 1.5 |

| 1 | 1.022 | 0.976 | 1.625 | 1.575 | 1.876 | 1.796 | 0.7 | 0.591 | 2.25 | 2.5 |

| 1 1/8 | 1.149 | 1.098 | 1.812 | 1.756 | 2.093 | 2.002 | 0.78 | 0.658 | 2.5 | 2.75 |

| 1 3/8 | 1.404 | 1.345 | 2.188 | 2.119 | 2.526 | 2.416 | 0.94 | 0.81 | 3 | 3.25 |

| 1 1/2 | 1.531 | 1.47 | 2.375 | 2.3 | 2.742 | 2.622 | 1.036 | 0.902 | 3.25 | 3.5 |

| 1 3/4 | 1.785 | 1.716 | 2.75 | 2.662 | 3.175 | 3.035 | 1.196 | 1.054 | 3.75 | 4 |

| 2 1/4 | 2.305 | 2.214 | 3.5 | 3.388 | 4.041 | 3.862 | 1.548 | 1.327 | 4.75 | 5 |

| 2 1/2 | 2.559 | 2.461 | 3.875 | 3.75 | 4.474 | 4.275 | 1.708 | 1.479 | 5.25 | 5.5 |

| 2 3/4 | 2.827 | 2.711 | 4.25 | 4.112 | 4.907 | 4.688 | 1.869 | 1.632 | 5.75 | 6 |

| 3 | 3.081 | 2.961 | 4.625 | 4.475 | 5.34 | 5.102 | 2.06 | 1.815 | 6.25 | 6 |

6. What are the applications of A193 B7 Bolt?

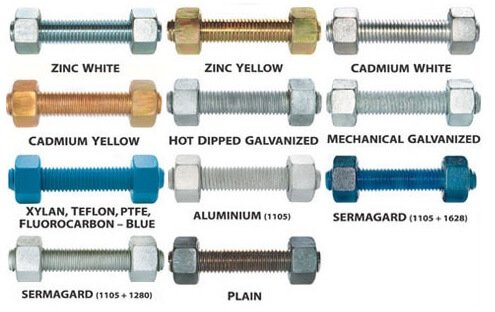

ASTM S193 Grade B7 bolts may have different types of finishes over them. The most common ones are:

- Plain finish bolts that are used for standard applications

- Hot-dip galvanized process

- Zinc-plated outer finishing

- Have a PTFE or a Xylan coating in order for the resistance to corrosion.

ASTM A193 Grade B7 bolts are most commonly used in pipe flange connections. Also, Grade B7 stud bolts are mostly used in pressure vessels that do not require any protection against corrosion and for instances with temperatures less than 750F.

7. Conclusion

ASTM A193 Grade B7 bolts, coupled with A194 Grade 2H Nuts are the most popular choice for bolting Carbon Steel Pipelines. This is because of its tensile strength and long durability.

ASTM A193 bolts are considered as the best choice for use in pressure valves, pressure vessel services, flanges and fittings due to their ability to withstand immense temperatures and high-pressure conditions. However, the coated bolts may have a low ability to withstand high temperatures and pressures than the plain A193 bolts.

Nevertheless, the ASTM A193 bolts are popularly used in the manufacturing industry in order to connect two or more parts together. As manufacturing processes of machinery and other materials are only increasing day by day throughout the world, the demand for A193 bolts only keeps getting higher with each passing day.

Don't forget to share this post!

Related Products

CONTACT US

Tell us your raw material and working details to get quotations within 24 hours.

WhatsApp Us: +86 159 27 555863

Want the best price & newest metal working machinery buying guide,tips and trends sent straightly to your box?Sign up for Armpro's monthly newsletter,we're free for your consultation and Offer you the most suitable working solutions!

The Buyer's Guide

- Tapping Machine: The Ultimate Buying Guide in 2021

- Electric Tapping Machines:the Ultimate Buying Guide in 2021

- Drilling Machine: The Ultimate Buying Guide in 2021

- Grinding Machine:The Ultimate Buying Guide in 2021

- Metal Band Saw Machine :The Complete Buying Guide in 2021

- Pneumatic Tapping Machine:The Complete Importing Guide in 2021

- Bench Tapping Machine:The Complete Buying Guide in 2021

- CNC Tapping Machine:The Complete Buying Guide In 2021

- Magnetic Base Drill Machine:The Ultimate Buying Guide in 2021

- Drilling And Tapping Machine:The Complete Buying Guide in 2021

Most Popular

Tell us your material or budget,we'll reply you ASAP within 24 hours