ISO Metric Thread Size Chart

- ISO Metric Threads are the most commonly used type of screw thread that has general-purpose applications. The international standard ISO 68-1 is used to define the design principles of ISO general-purpose metric screw threads which are also known as M threads.

1. What is the ISO Metric Thread parameter?

ISO metric threads are a standardized measuring system used to measure and specify threaded fasteners like bolts and nuts. There are several parameters that can be found in the ISO metric threads.

These parameters ensure that high compatibility and interchangeability of threaded components are achieved by providing a comprehensive specification for metric threads.

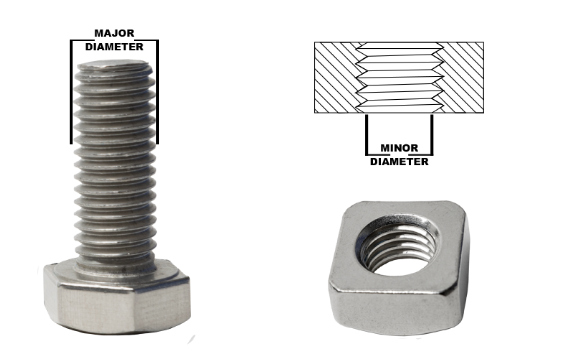

- Thread Pitch (P): The distance between adjacent threads along the fastener's axis is the thread pitch.

- Major Diameter (D): The outer diameter of the threaded part of the fastener.

- Minor diameter (d): The diameter at the bottom of the thread's grooves is the minor diameter.

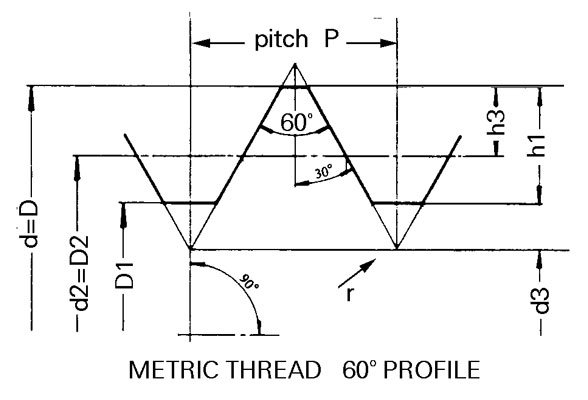

- Pitch diameter (d2): It is a theoretical diameter which lies between the major and minor diameters. This parameter is used for various calculations and imperative in ensuring the proper engagement of the thread.

- Thread angle: The ISO metric thread standard has a thread angle of 60-degrees which is a common system in many threads.

- Thread tolerance: ISO metric threads possess predefined tolerances for major and minor diameters and the diameter of the pitch. These tolerances enable to make sure that threads may fit together correctly even if they are from different manufacturers.

- Thread series: ISO metric threads are produced in several series which includes the coarse thread series that is designated as 'M' and the fine thread series that is designated as 'MF'.

These parameters are considered essential in various industries where threaded fasteners have wide applications like automotive to construction.

2. What is the ISO Metric Thread size chart

The ISO metric thread size chart is a standard table that provides a standardized reference for the specification of metric threads, including the major diameter (D), pitch (P), and thread designation. Below is a version of the standard size chart for ISO metric threads.

The above chart shows the standard specifications for ISO metric threads. include Coarser and fine threads, Based on your requirements you can go through the size chart to choose the most suitable ISO metric thread to suit your needs and requirements.

Metric Threads - Coarser Threads

| Thread | Major Diameter

(d=D) |

Pitch

(p) |

Root

Radius (r) |

Pitch

Diameter (d2=D2) |

Minor

Diameter Male Thread (d3) |

Minor

Diameter Female Thread (D1) |

Thread Height

Male Thread (h3) |

Thread Height

Female Thread (H1) |

Tap Drill Diameter |

|---|---|---|---|---|---|---|---|---|---|

| M1 | 1 | 0.25 | 0.036 | 0.838 | 0.693 | 0.729 | 0.153 | 0.135 | 0.75 |

| M1.1 | 1.1 | 0.25 | 0.036 | 0.938 | 0.793 | 0.829 | 0.153 | 0.135 | 0.85 |

| M1.2 | 1.2 | 0.25 | 0.036 | 1.038 | 0.893 | 0.929 | 0.153 | 0.135 | 0.95 |

| M1.4 | 1.4 | 0.3 | 0.043 | 1.205 | 1.032 | 1.075 | 0.184 | 0.162 | 1.1 |

| M1.6 | 1.6 | 0.35 | 0.051 | 1.373 | 1.171 | 1.221 | 0.215 | 0.189 | 1.25 |

| M1.8 | 1.8 | 0.35 | 0.051 | 1.573 | 1.371 | 1.421 | 0.215 | 0.189 | 1.45 |

| M2 | 2 | 0.4 | 0.058 | 1.74 | 1.509 | 1.567 | 0.245 | 0.217 | 1.6 |

| M2.2 | 2.2 | 0.45 | 0.065 | 1.908 | 1.648 | 1.713 | 0.276 | 0.244 | 1.75 |

| M2.5 | 2.5 | 0.45 | 0.065 | 2.208 | 1.948 | 2.013 | 0.276 | 0.244 | 2.05 |

| M3 | 3 | 0.5 | 0.072 | 2.675 | 2.387 | 2.459 | 0.307 | 0.271 | 2.5 |

| M3.5 | 3.5 | 0.6 | 0.087 | 3.11 | 2.764 | 2.85 | 0.368 | 0.325 | 2.9 |

| M4 | 4 | 0.7 | 0.101 | 3.545 | 3.141 | 3.242 | 0.429 | 0.379 | 3.3 |

| M4.5 | 4.5 | 0.75 | 0.108 | 4.013 | 3.58 | 3.688 | 0.46 | 0.406 | 3.8 |

| M5 | 5 | 0.8 | 0.115 | 4.48 | 4.019 | 4.134 | 0.491 | 0.433 | 4.2 |

| M6 | 6 | 1 | 0.144 | 5.35 | 4.773 | 4.917 | 0.613 | 0.541 | 5 |

| M7 | 7 | 1 | 0.144 | 6.35 | 5.773 | 5.917 | 0.613 | 0.541 | 6 |

| M8 | 8 | 1.25 | 0.18 | 7.188 | 6.466 | 6.647 | 0.767 | 0.677 | 6.8 |

| M9 | 9 | 1.25 | 0.18 | 8.188 | 7.466 | 7.647 | 0.767 | 0.677 | 7.8 |

| M10 | 10 | 1.5 | 0.217 | 9.026 | 8.16 | 8.376 | 0.92 | 0.812 | 8.5 |

| M11 | 11 | 1.5 | 0.217 | 10.026 | 9.16 | 9.376 | 0.92 | 0.812 | 9.5 |

| M12 | 12 | 1.75 | 0.253 | 10.863 | 9.853 | 10.106 | 1.074 | 0.947 | 10.2 |

| M14 | 14 | 2 | 0.289 | 12.701 | 11.564 | 11.835 | 1.227 | 1.083 | 12 |

| M16 | 16 | 2 | 0.289 | 14.701 | 13.546 | 13.835 | 1.227 | 1.083 | 14 |

| M18 | 18 | 2.5 | 0.361 | 16.376 | 14.933 | 15.394 | 1.534 | 1.353 | 15.5 |

| M20 | 20 | 2.5 | 0.361 | 18.376 | 16.933 | 17.294 | 1.534 | 1.353 | 17.5 |

| M22 | 22 | 2.5 | 0.361 | 20.376 | 18.933 | 19.294 | 1.534 | 1.353 | 19.5 |

| M24 | 24 | 3 | 0.433 | 22.051 | 20.319 | 20.752 | 1.84 | 1.624 | 21 |

| M27 | 27 | 3 | 0.433 | 25.051 | 23.319 | 23.752 | 1.84 | 1.624 | 24 |

| M30 | 30 | 3.5 | 0.505 | 27.727 | 25.706 | 26.211 | 2.147 | 1.894 | 26.5 |

| M33 | 33 | 3.5 | 0.505 | 30.727 | 28.706 | 29.211 | 2.147 | 1.894 | 29.5 |

| M36 | 36 | 4 | 0.577 | 33.402 | 31.093 | 31.67 | 2.454 | 2.165 | 32 |

| M39 | 39 | 4 | 0.577 | 36.402 | 34.093 | 34.67 | 2.454 | 2.165 | 35 |

| M42 | 42 | 4.5 | 0.65 | 39.077 | 36.479 | 37.129 | 2.76 | 2.436 | 37.5 |

| M45 | 45 | 4.5 | 0.65 | 42.077 | 39.479 | 40.129 | 2.76 | 2.436 | 40.5 |

| M48 | 48 | 5 | 0.722 | 44.752 | 41.866 | 42.857 | 3.067 | 2.706 | 43 |

| M52 | 52 | 5 | 0.722 | 48.752 | 45.866 | 46.857 | 3.067 | 2.706 | 47 |

| M56 | 56 | 5.5 | 0.794 | 52.428 | 49.252 | 50.046 | 3.374 | 2.977 | 50.5 |

| M60 | 60 | 5.5 | 0.794 | 56.428 | 53.252 | 54.046 | 3.374 | 2.977 | 54.5 |

| M64 | 64 | 6 | 0.866 | 60.103 | 56.639 | 57.505 | 3.681 | 3.248 | 58 |

| M68 | 68 | 6 | 0.866 | 64.103 | 60.639 | 61.505 | 3.681 | 3.248 | 62 |

| Thread

Size |

Major

Diameter d=D |

Pitch

p |

Root

Radius r |

Pitch

Diameter d2=D2 |

Minor

Diameter Male Thread d3 |

Minor

Diameter Female Thread D1 |

Thread

Height Male Thread h3 |

Thread

Height Female Thread H1 |

Tap

Drill Diameter |

|---|---|---|---|---|---|---|---|---|---|

| M1.0 x 0.2 | 1 | 0.2 | 0.029 | 0.87 | 0.755 | 0.783 | 0.123 | 0.108 | 0.8 |

| M1.1 x 0.2 | 1.1 | 0.2 | 0.029 | 0.97 | 0.855 | 0.883 | 0.123 | 0.108 | 0.9 |

| M1.2 x 0.2 | 1.2 | 0.2 | 0.029 | 1.07 | 0.955 | 0.983 | 0.123 | 0.108 | 1 |

| M1.4 x 0.2 | 1.4 | 0.2 | 0.029 | 1.27 | 1.155 | 1.183 | 0.123 | 0.108 | 1.2 |

| M1.6 x 0.2 | 1.6 | 0.2 | 0.029 | 1.47 | 1.355 | 1.383 | 0.123 | 0.108 | 1.4 |

| M1.8 x 0.2 | 1.8 | 0.2 | 0.029 | 1.67 | 1.555 | 1.583 | 0.123 | 0.108 | 1.6 |

| M2 x 0.25 | 2 | 0.25 | 0.036 | 1.838 | 1.693 | 1.729 | 0.153 | 0.135 | 1.75 |

| M2.2 x 0.25 | 2.2 | 0.25 | 0.036 | 2.038 | 1.893 | 1.929 | 0.153 | 0.135 | 1.95 |

| M2.5 x 0.35 | 2.5 | 0.35 | 0.051 | 2.273 | 2.071 | 2.121 | 0.215 | 0.189 | 2.1 |

| M3 x 0.35 | 3 | 0.35 | 0.051 | 2.773 | 2.571 | 2.621 | 0.215 | 0.189 | 2.6 |

| M3.5 x 0.35 | 3.5 | 0.35 | 0.051 | 3.273 | 3.071 | 3.121 | 0.215 | 0.189 | 3.1 |

| M4 x 0.5 | 4 | 0.5 | 0.072 | 3.675 | 3.387 | 3.459 | 0.307 | 0.271 | 3.5 |

| M4.5 x 0.5 | 4.5 | 0.5 | 0.072 | 4.175 | 3.887 | 3.959 | 0.307 | 0.271 | 4 |

| M5 x 0.5 | 5 | 0.5 | 0.072 | 4.675 | 4.387 | 4.459 | 0.307 | 0.271 | 4.5 |

| M5.5 x 0.5 | 5.5 | 0.5 | 0.072 | 5.175 | 4.887 | 4.959 | 0.307 | 0.271 | 5 |

| M6 x 0.75 | 6 | 0.75 | 0.108 | 5.513 | 5.08 | 5.188 | 0.46 | 0.406 | 5.2 |

| M7 x 0.75 | 7 | 0.75 | 0.108 | 6.513 | 6.08 | 6.188 | 0.46 | 0.406 | 6.2 |

| M8 x 0.75 | 8 | 0.75 | 0.108 | 7.513 | 7.08 | 7.188 | 0.46 | 0.406 | 7.2 |

| M8 x 1.0 | 8 | 1 | 0.144 | 7.35 | 6.773 | 6.917 | 0.613 | 0.541 | 7 |

| M9 x 0.75 | 9 | 0.75 | 0.108 | 8.513 | 8.08 | 8.188 | 0.46 | 0.406 | 8.2 |

| M9 x 1 | 9 | 1 | 0.144 | 8.35 | 7.773 | 7.917 | 0.613 | 0.541 | 8 |

| M10 x 0.75 | 10 | 0.75 | 0.108 | 9.513 | 9.08 | 9.188 | 0.46 | 0.406 | 9.2 |

| M10 x 1 | 10 | 1 | 0.144 | 9.35 | 8.773 | 8.917 | 0.613 | 0.541 | 9 |

| M10 x 1.25 | 10 | 1.25 | 0.18 | 9.188 | 8.466 | 8.647 | 0.767 | 0.677 | 8.8 |

| M11 x 0.75 | 11 | 0.75 | 0.108 | 10.513 | 10.08 | 10.188 | 0.46 | 0.406 | 10.2 |

| M11 x 1 | 11 | 1 | 0.144 | 10.35 | 9.773 | 9.917 | 0.613 | 0.541 | 10 |

| M12 x 1 | 12 | 1 | 0.144 | 11.35 | 10.773 | 10.917 | 0.613 | 0.541 | 11 |

| M12 x 1.25 | 12 | 1.25 | 0.18 | 11.188 | 10.466 | 10.647 | 0.767 | 0.677 | 10.8 |

| M12 x 1.5 | 12 | 1.5 | 0.217 | 11.026 | 10.16 | 10.376 | 0.92 | 0.812 | 10.5 |

| M14 x 1 | 14 | 1 | 0.144 | 13.35 | 12.773 | 12.917 | 0.613 | 0.541 | 13 |

| M14 x 1.25 | 14 | 1.25 | 0.18 | 13.188 | 12.466 | 12.647 | 0.767 | 0.677 | 12.8 |

| M14 x 1.5 | 14 | 1.5 | 0.217 | 13.026 | 12.16 | 12.376 | 0.92 | 0.812 | 12.5 |

| M15 x 1 | 15 | 1 | 0.144 | 14.35 | 13.773 | 13.917 | 0.613 | 0.541 | 14 |

| M15 x 1.5 | 15 | 1.5 | 0.217 | 14.026 | 13.16 | 13.376 | 0.92 | 0.812 | 13.5 |

| M16 x 1 | 16 | 1 | 0.144 | 15.35 | 14.773 | 14.917 | 0.613 | 0.541 | 15 |

| M16 x 1.5 | 16 | 1.5 | 0.217 | 15.026 | 14.16 | 14.376 | 0.92 | 0.812 | 14.5 |

| M17 x 1 | 17 | 1 | 0.144 | 16.35 | 15.733 | 15.917 | 0.613 | 0.541 | 16 |

| M17 x 1.5 | 17 | 1.5 | 0.217 | 16.026 | 15.16 | 15.376 | 0.92 | 0.812 | 15.5 |

| M18 x 1 | 18 | 1 | 0.144 | 17.35 | 16.773 | 16.917 | 0.613 | 0.541 | 17 |

| M18 x 1.5 | 18 | 1.5 | 0.217 | 17.026 | 16.16 | 16.376 | 0.92 | 0.812 | 16.5 |

| M18 x 2 | 18 | 2 | 0.289 | 16.701 | 15.546 | 15.835 | 1.227 | 1.083 | 16 |

| M20 x 1.0 | 20 | 1 | 0.144 | 19.35 | 18.773 | 18.917 | 0.613 | 0.541 | 19 |

| M20 x 1.5 | 20 | 1.5 | 0.217 | 19.026 | 18.16 | 18.376 | 0.92 | 0.812 | 18.5 |

| M20 x 2.0 | 20 | 2 | 0.289 | 18.701 | 17.546 | 17.835 | 1.227 | 1.083 | 18 |

| M22 x 1.0 | 22 | 1 | 0.144 | 21.35 | 20.773 | 20.917 | 0.613 | 0.541 | 21 |

| M22 x 1.5 | 22 | 1.5 | 0.217 | 21.026 | 20.16 | 20.376 | 0.92 | 0.812 | 20.5 |

| M22 x 2.0 | 22 | 2 | 0.289 | 20.701 | 19.546 | 19.835 | 1.227 | 1.083 | 20 |

| M24 x 1.0 | 24 | 1 | 0.144 | 23.35 | 22.773 | 22.917 | 0.613 | 0.541 | 23 |

| M24 x 1.5 | 24 | 1.5 | 0.217 | 23.026 | 22.16 | 22.376 | 0.92 | 0.812 | 22.5 |

3. What is the application of the ISO Metric Thread?

ISO Metric threads have a large range of applications across various industries around the world. This is due to their standardized design and size. Some such industries where ISO metric threads are used are given below.

| 1. Manufacturing and engineering industry |

| ISO metric threads are very often used in the manufacturing and engineering industry for the manufacturing of machinery, components, and equipment. They are used mostly as they provide a standardized way to connect and secure parts of the machinery, thereby ensuring interchangeability and compatibility. |

| 2. Construction industry |

| ISO metric threads are used in the construction industry to assemble structural components, securing the scaffolding, and fastening various materials of buildings. |

| 3. Aerospace industry |

| Aerospace engineering highly relies on precision. metric threads are considered very suitable for assembling aircraft components, securing critical systems and ensuring the integrity of the aircraft considering its structure. |

| 4. Automotive industry |

| ISO metric threads are very commonly used in automobiles. They are used to secure various components including engine parts, fasteners and chassis components. |

| 5. Electronics industry |

| Metric threads are used in the electronics industry to secure devices, enclosures and assemblies thereby ensuring proper alignment and electrical connections. |

| 6. Medical devices manufacturing industry |

| ISO metric threads are used in the manufacturing of medical devices. Metric threads ensure the proper assembly and function of various instruments and equipment. |

| 7. Plumbing and pipe fittings manufacturing industry |

| ISO metric threads are used in the manufacturing of plumbing and fluid systems in order to connect pipes, valves, and fittings. This also ensures a leak-tight seal. |

| 8. Fasteners manufacturing industry |

| Metric bolts, screws, and nuts equipped with ISO metric threads are available for general purpose use and are commonly found in almost all hardware stores. |

| 9. Bicycles and sports equipment |

| ISO metric threads are used in the assembly of bicycles, sporting equipment and outdoor gear in order to ensure that the equipment has the highest stability and safety. |

| 10. Furniture equipment manufacturing industry |

| ISO metric threads are used in the assembly of furniture, home appliances, consumer goods and other household products. Using metric threads to manufacture these products makes it easier to assemble and disassemble these products. |

4. How to make an ISO Metric Thread?

Creating ISO metric threads require high knowledge of precision, especially if the threads are to be used for critical applications. Using the correct tap or die sizes and lubricating the threading tool is very important in order to achieve accurate and well-formed threads. Their specifications must be carefully crafted as they are itself used to give high-precision solutions. ISO metric threads consist of a symmetrical V-shaped thread, where the V has an angle of 60° in the plane of the thread axis. The depth of the thread id about 0.54125 x pitch and the outermost ⅛ and the innermost ¼ of the height are cut off from the profile of the V-shape.

5. Conclusion

In conclusion, ISO metric threads serve as the sole language of precision engineering. They provide a standardized system for measuring the thread and specifications. The ability to apply them in a wide range of applications in various industries, from aerospace to construction and electronics.

The ISO metric threads standard ensures that the products contain compatibility and interchangeability. Moreover, they contribute to the safety, quality and reliability of the products and machinery that are distributed worldwide. The simplicity and the precision of ISO metric threads make it an invaluable tool for engineers, manufacturers, constructors, and designers, as they simplify the complexities of threaded fasteners.

With the advancement and globalization that the industries are undergoing currently, ISO metric threads remain a solid ground for efficient production, maintenance, and repair. Therefore, whether you are planning to build a skyscraper, assemble an engine for the latest model of a car, or even in the middle of the process of designing the latest technological innovation, ISO metric threads will continue to have a vital role in shaping the future of the whole world.

Don't forget to share this post!

Related Products

CONTACT US

Tell us your raw material and working details to get quotations within 24 hours.

WhatsApp Us: +86 159 27 555863

Want the best price & newest metal working machinery buying guide,tips and trends sent straightly to your box?Sign up for Armpro's monthly newsletter,we're free for your consultation and Offer you the most suitable working solutions!

The Buyer's Guide

- Tapping Machine: The Ultimate Buying Guide in 2021

- Electric Tapping Machines:the Ultimate Buying Guide in 2021

- Drilling Machine: The Ultimate Buying Guide in 2021

- Grinding Machine:The Ultimate Buying Guide in 2021

- Metal Band Saw Machine :The Complete Buying Guide in 2021

- Pneumatic Tapping Machine:The Complete Importing Guide in 2021

- Bench Tapping Machine:The Complete Buying Guide in 2021

- CNC Tapping Machine:The Complete Buying Guide In 2021

- Magnetic Base Drill Machine:The Ultimate Buying Guide in 2021

- Drilling And Tapping Machine:The Complete Buying Guide in 2021

Most Popular

Tell us your material or budget,we'll reply you ASAP within 24 hours